Tailings: development journey of the Tailings Slurrification Unit (TSU)

-

Stefan

GroenheideMining consultant

As recent dam disasters have shown, one of the most urgent topics in the tailings industry is dam de-characterization. Dam de-characterization is the process of reshaping of the terrain of a tailings dam and partially or totally removing tailings from the reservoir. Earlier this year I wrote a blog on the opportunities and risks of tailings. Here I showed how the re-mining of tailings, either for reprocessing or dam de-characterization, overlaps with features found within Royal IHC’s dredging technology.

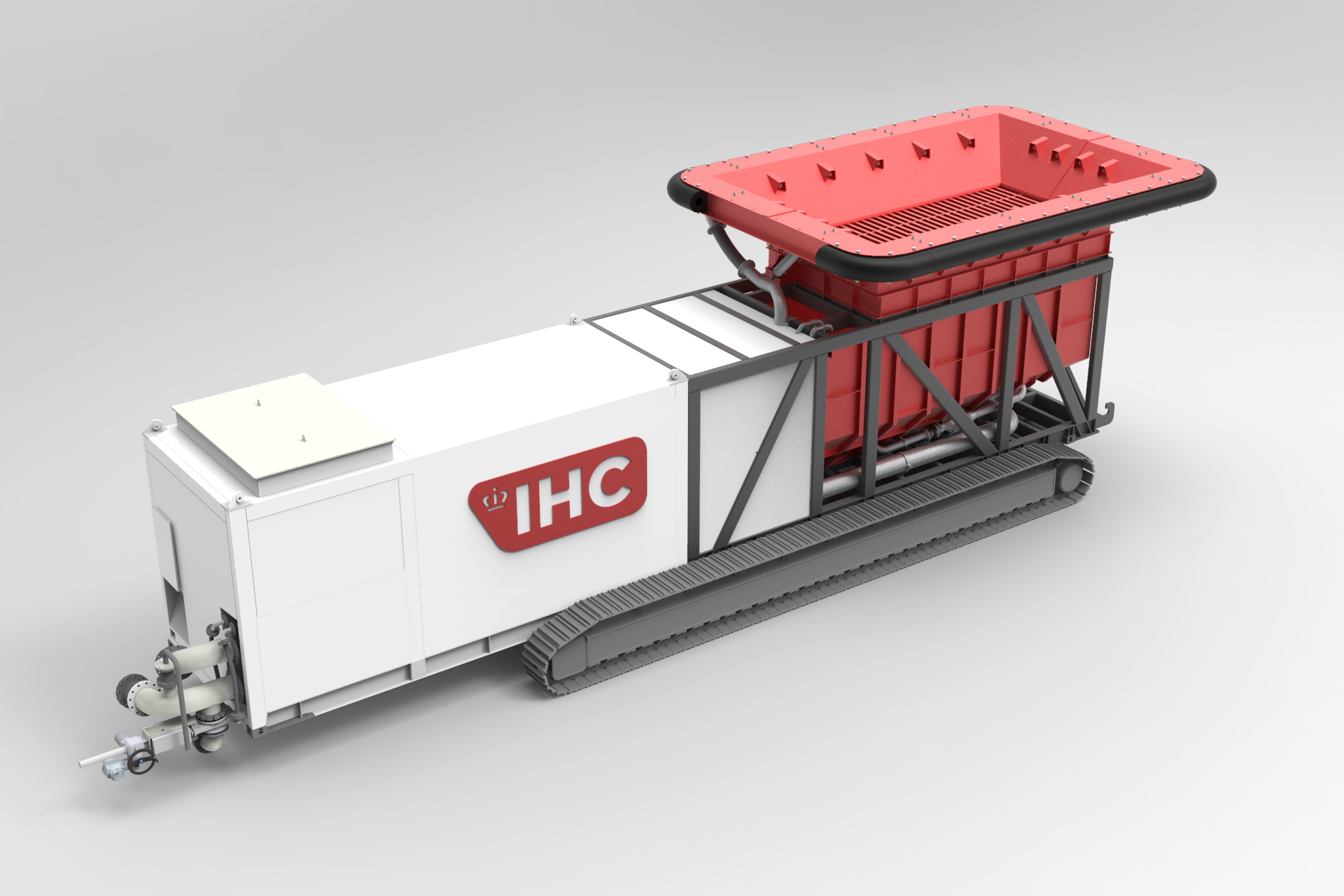

Therefore it’s only logical that we further develop equipment to help our clients in these processes. One of the products that we have developed is the Tailings Slurrification Unit, or TSU in short. But what does this unit do and why did we choose to develop this particular type of equipment? Let’s go on a little development journey!

Identify the weak link in the chain that needs to be improved

Most mining companies are not known as being front-runners in adopting new technologies. This comes from the fact that mining operations are (very) long-term projects with huge investments. So, when a company decides to mine a deposit, they have to know that the equipment that they purchased will work and that it meets the production rates as assumed in the design process. This is also the reason that miners approach the de-characterization process of a tailings dam in a similar fashion: excavators and trucks work in regular mining, so it should work with tailings re-handling as well, right?

Well, as I discussed in my previous blog, the characteristics of tailings are very different from fresh rock. The main differences with fresh rock are that tailings are crushed and fine-grained material and they are deposited with water. These characteristics combined with muddy roads that have low bearing capacity make truck transport one of the worst possible options. And then we haven’t even talked about the transport costs and the carbon footprint of these operations.

So here you have it, weak link identified! The equipment we would develop had to improve the transport capabilities of a tailings re-handling operation, while simultaneously reducing overall transport costs and CO2 emissions.

Replace trucks with a slurry pipeline

The starting point for the design of the TSU is the replacement of a fleet of trucks with a slurry pipeline, which requires the use of a pump unit. More often than not, the likely operational environment of a tailings dam is in a very hilly to mountainous region. Next to that, the new discharge point is generally located far away from the dam. Therefore the operation requires a pump that is ready for this challenge, and just the right match has been found in the HRHD series pumps that have recently been developed by Royal IHC. This pump is able to generate much higher pressures than conventional pumps, which is perfectly suited for our application.

Secondly, the TSU would need to be able to work with existing equipment of the mining operation as we are only replacing a single chain in the process. In order to work with existing excavators, the TSU required the installation of a large feed hopper to be able to receive a full bucket load of material. Even though tailings are fine-grained material, you never know what has been dumped in the dams in the past. That’s why the design includes the placement of a grizzly screen at the top of the slurrification tank. The grizzly screen works as a fail-safe to catch any unexpected surprise large rocks and protecting the pump in the process. The entire feed hopper can be tilted to clean the screen and remove any material not passing, which increase both operational efficiency and uptime.

Secondly, the TSU would need to be able to work with existing equipment of the mining operation as we are only replacing a single chain in the process. In order to work with existing excavators, the TSU required the installation of a large feed hopper to be able to receive a full bucket load of material. Even though tailings are fine-grained material, you never know what has been dumped in the dams in the past. That’s why the design includes the placement of a grizzly screen at the top of the slurrification tank. The grizzly screen works as a fail-safe to catch any unexpected surprise large rocks and protecting the pump in the process. The entire feed hopper can be tilted to clean the screen and remove any material not passing, which increase both operational efficiency and uptime.

Lastly, the TSU must be easily transportable to site and be easily moveable during the operation. So, the basis of the our design was a standard sea freight container containing the entire slurry bin and pumping unit making it road transportable. The container is installed on a sliding skid that can be pulled by a dozer that is readily available on the mine site.

Combining all these components, we developed a unit that:

- is able to transport up to 250 m3 of excavated tailings per hour.

- is suited to work with existing machinery such as excavators and dozers.

- is easy to transport and move.

- is electrically powered, reducing the local CO2 emissions to practically zero!

All in all, a single TSU and a slurry pipeline can do the same amount of work of approximately 10 mine trucks. Thereby reducing the costs of transport per in-situ cubic metres tailings enormously. So not only can the TSU replace an entire fleet of mine trucks, but this also positively impacts the carbon footprint of the operation.

What is next in this journey?

So where do we go from here? Developing a concept is one thing, but bringing the concept to life is another. We have partnered with a launching customer to test the TSU at one of their operations. My colleagues and I are working very hard to complete the engineering and construction of critical components is already in the works. The plan is to have the unit ready for the test operation in Q2 2022. Of course I will update you on the results of the tests to wrap-up this complete journey from problem to solution!

Written by

Stefan Groenheide

Mining consultant

Want to know more about our TSU?

Fill in the form and our experts will contact you.