Learning the ropes

At Royal IHC, we pride ourselves on understanding which equipment is best for an operation, right down to the choice of rope.

Although steel wire rope (SWR) has traditionally been the preferred choice for lifting and hoisting in offshore operations, we’re pleased to see that our R&D programmes have opened the debate on the advantages of fibre rope.

It can be as strong as steel but is six to seven times lighter. In addition, when SWR breaks, there is a danger of people being hit due to the aggressive recoil. This risk is significantly reduced when using fibre rope.

Years ago, when Royal IHC’s attention began to focus on the emerging deep-sea markets, high strength fibre rope equipment became an important sector for us. For many of these applications, it was simply not possible to use conventional SWR so there was an urgent need to develop a fibre rope solution.

Putting it to the test

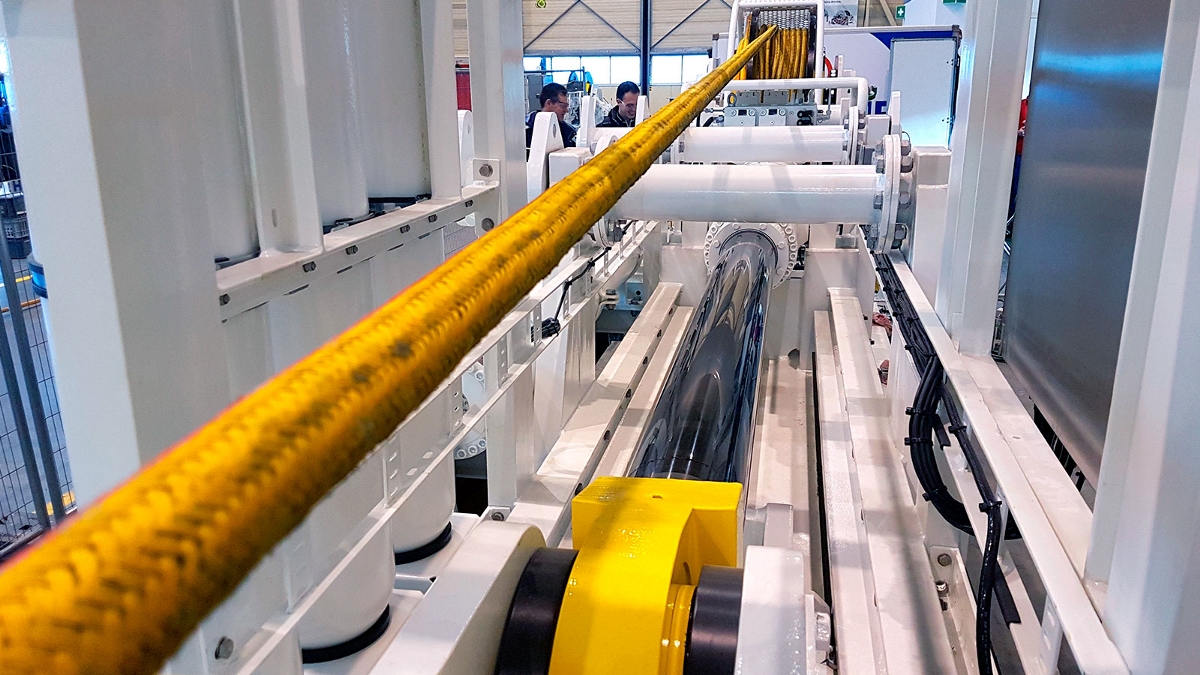

An important step in our research was the development of a test facility, which was used to gain insight into the characteristics of all types of fibre rope.

Through our tests, we gained a greater understanding of the performance values of fibre rope and can now tailor the characteristics of the rope precisely to its intended purpose.

Wider applications

Royal IHC’s fibre rope applications are now much wider than deep sea only, significant benefits can be seen in other markets. One example of this is the Delta Escort Tug. It has a revolutionary escort winch, which was developed and optimised specifically for fibre rope.

The unique configuration of components provides an extended lifetime of the equipment and offers enhanced safety for the operators.

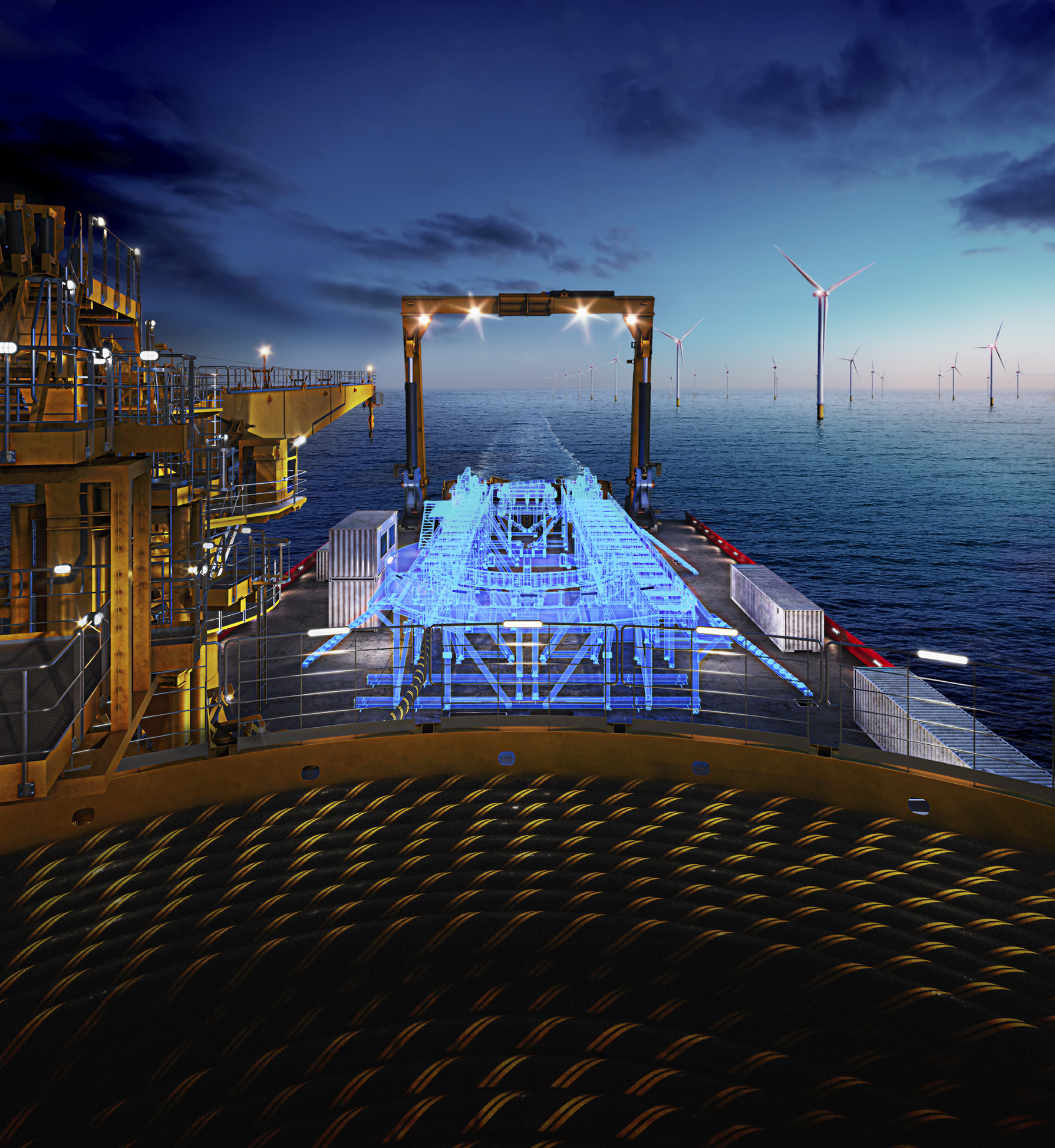

In addition, IHC Mission Equipment has developed and delivered tugger winches to IHC IQIP for the handling of a noise mitigation screens for offshore wind piling operations. Fibre rope was a customer requirement for its superior handling and safety properties compared to SWR.

The advantages of fibre rope are also evident in other sectors, such as the selection of barge-mooring ropes for the world’s largest cutter suction dredger, SPARTACUS, for which special winches have been designed for the handling process.

Here to stay

Our findings show that fibre rope is here to stay and will increasingly be used in the future. While rope life prediction is improving, it still remains a challenge. However, many of the potential problems are overcome when fibre rope equipment is designed to match its unique properties.

Written by

Maurits van Wezel

Research & Developer

Ask a consultant

Discuss your options with a consultant.