Pioneering draghead design with CFD

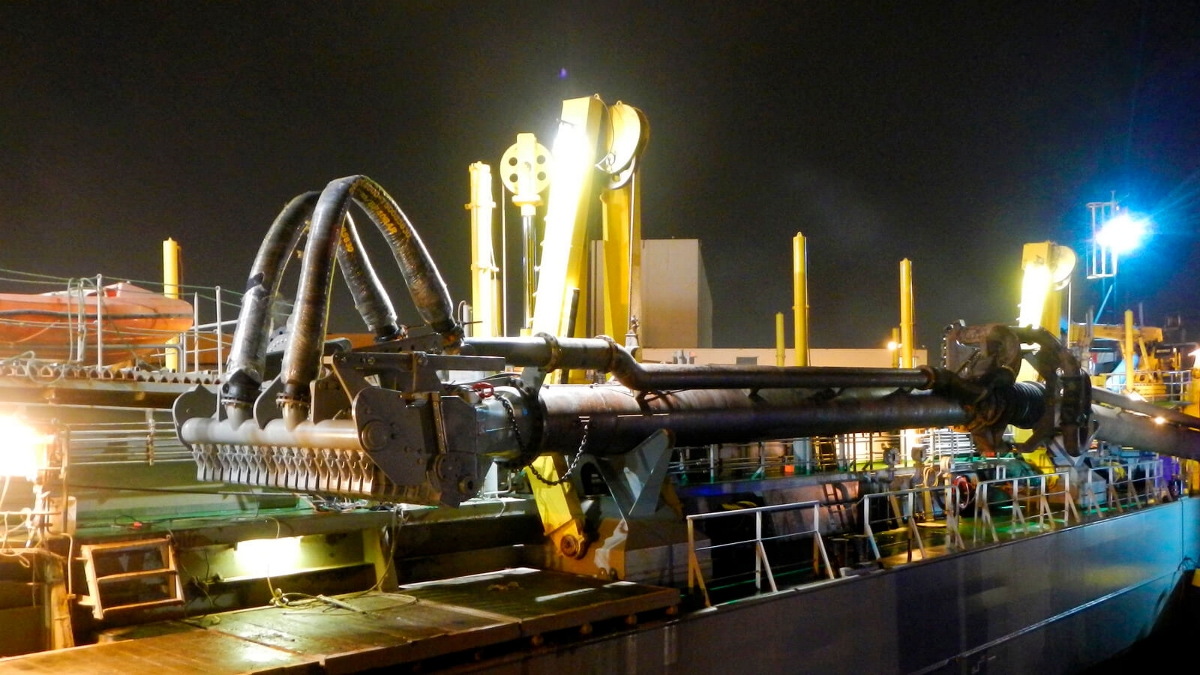

A drag head is a key component that influences the entire production of a trailing suction hopper dredger. However, due to varying dredging conditions and its position on the seabed, it is difficult to understand how its efficiency can be optimised.

Royal IHC has been working with the Technical University of Delft to develop new CFD (computational fluid dynamics) techniques to simulate different types of drag heads. This enables us to gain a detailed insight into the processes taking place inside it.

Fine-tuning the model

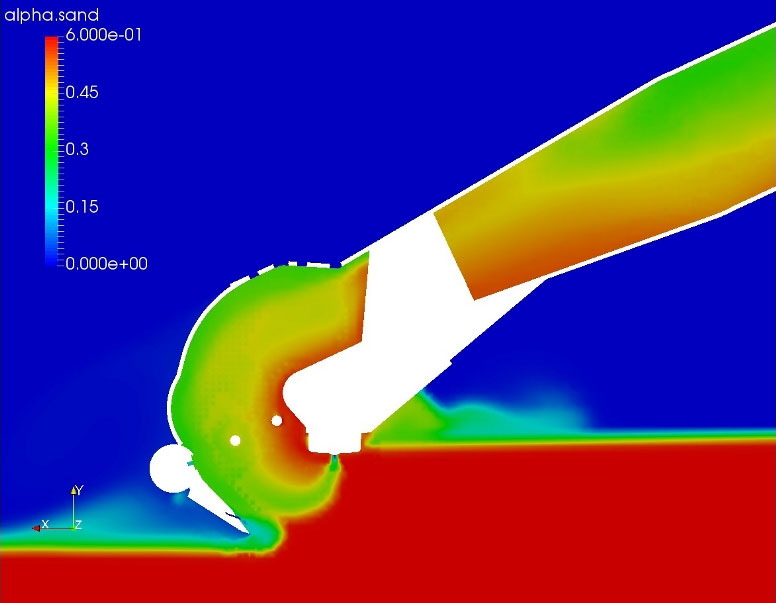

As a pioneering company for two-phase models – simulating soil and water – we focused on the influence of geometry, jet location and different soil types. This has led to a greater understanding of flow, pressure and density variations inside a drag head.

We evaluated the flow patterns of several excavating drag heads. This provided detailed information about the behaviour of the flows and pressures inside a drag head and highlighted the optimum geometry, as well as how to minimise the flow resistance.

Using CFD simulations, different jet water nozzle positions were evaluated. This was to determine the optimal placement in order to deliver high production rates and the most homogenous mixture in the drag head.

In addition, modelling conducted in settings based on medium fine and fine sands, demonstrated that the jets penetrate deepest in medium fine soils. Visualising the mixture flow allows us to optimise a drag head for a specific type of soil, resulting in optimal production levels.

With regards to maintenance, we are able to accurately identify spots within the drag head that will be most prone to wear. Using the CFD insights, the geometry of a drag head can be optimised or locally reinforced with wear resistant material.

Innovating new concepts

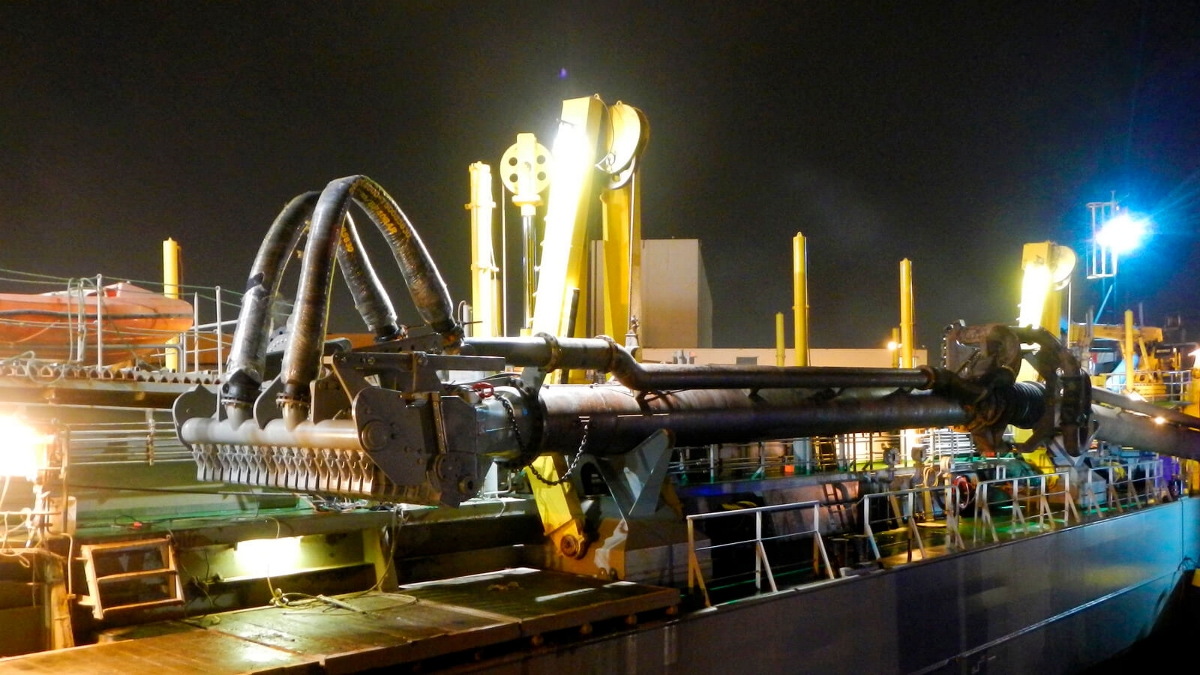

To prove that CFD is an effective design tool, Royal IHC used it to develop the new Mighty Dragon drag head for clay – a notoriously difficult soil type to excavate. The subsequent smooth shape, combined with optimum jet nozzle locations, results in a drag head design that is optimised for dredging clay without blockage. There are no recirculation zones, which equates to less wear and a lower flow resistance.

Following promising laboratory tests, the first Mighty Dragon model was tested on a TSHD in operational conditions. It was able to dredge clay with a stiffness of 75kPa, without clogging, which could not be done before. It also demonstrated a better performance in silt and sand.

Following on from this success, Royal IHC is looking into other ways CFD can be used to further optimise and develop new designs. For us, CFD is becoming a crucial tool for researching and creating innovative dredging components and systems.

Written by

Bram van Spaendonk

Project Manager R&D

Want to know more about the efficiency of our drag heads?

Fill in the form and one of our experts will contact you.