IHC Dredging

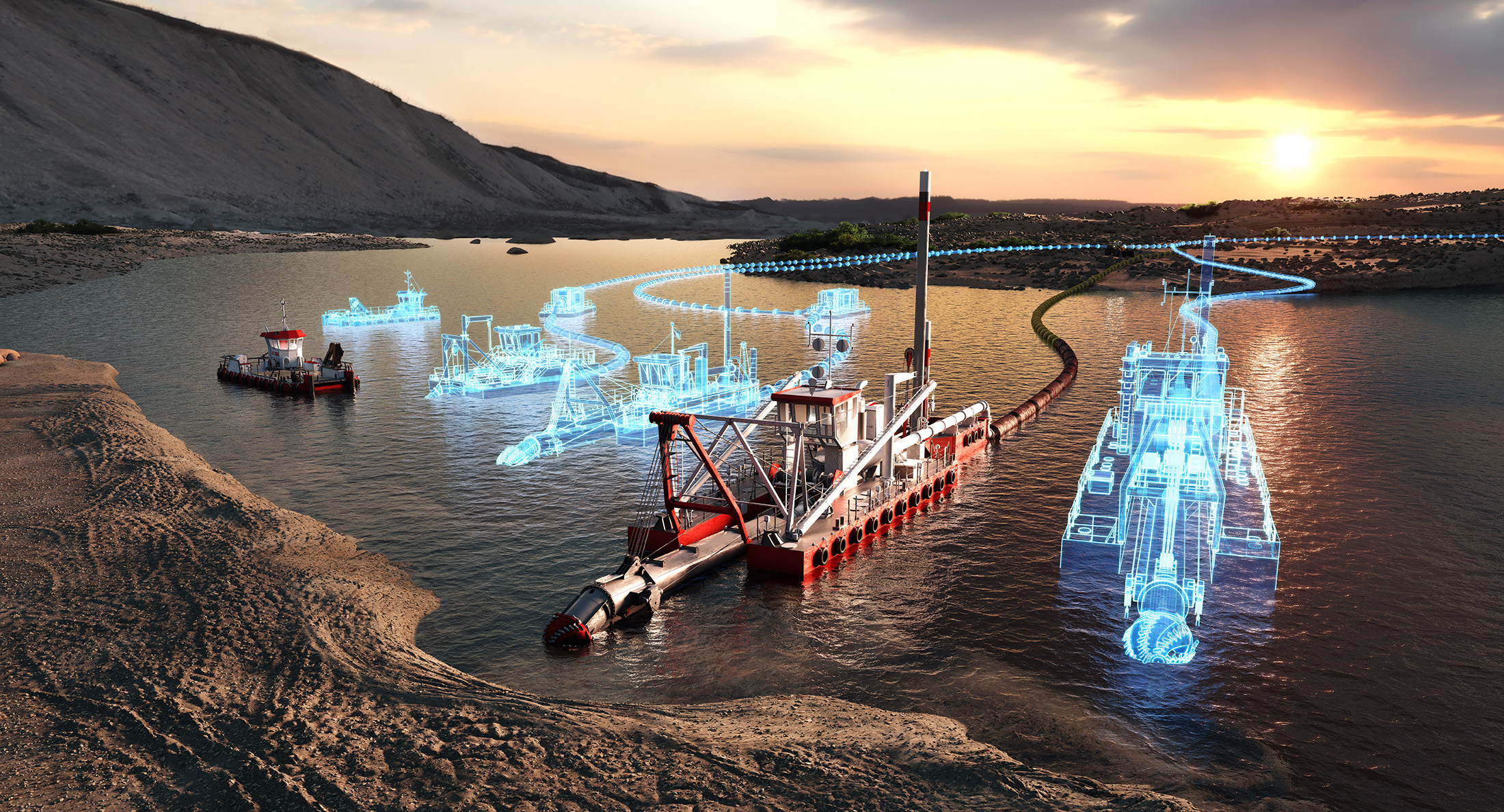

Preparing you for tomorrow's challenges by means of state of the art solutions and services to make your dredging operations more efficient and sustainable.

Jump to:

-

Vessels

Whatever your dredging project, we design and build a variety of standardised and custom-built dredging vessels to suit your needs.

-

Equipment

Boosting your operations with efficient and integrated dredging equipment.

-

Services

Keeping your dredging uptime high with our integrated, full service approach.

What is dredging?

Dredging is the removal of underwater soil, like sand or gravel, and its transport. Although it sounds like a simple act, it is one that has helped shape our world. Do you want to know more about what dredging entails, its importance and how this process works?

Mastering your dredging challenges

As a company operating in the dredging market, you face a number of challenges. At IHC Dredging we not only fully understand these challenges, we also want to work with you to find the best approach and solution. Different issues ask for different approaches, dredgers, dredging equipment and services. Read all about it in the following articles.

Integrated dredging solutions

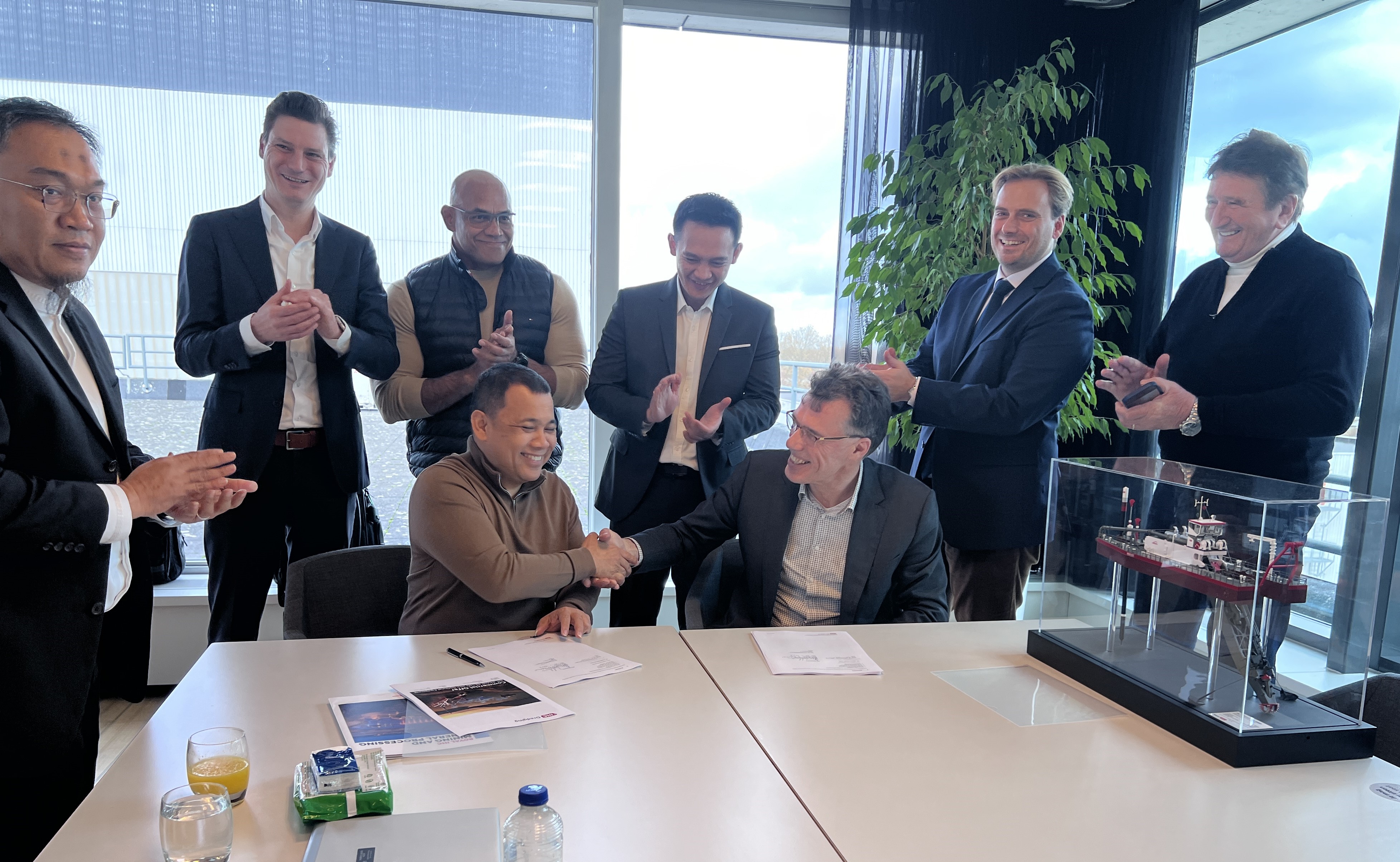

We aim to deliver a totally integrated dredging solution and we believe that designing, constructing and putting into operation the most efficient dredger is only possible in close collaboration with you, our customer. Key to our longstanding success is knowing the circumstances in which a vessel will operate.

Project we're proud of

The SPARTACUS sets a new standard for the dredging industry and solidifies our position as market leader in the field of dredgers. Not only because the SPARTACUS is by far the largest and most powerful cutter suction dredger in the world, and the first to run on LNG, but also because of the many innovations on board.

View the SPARTACUS case

View other cases we're proud of

Suitable for every dredging project

From the very first phase of a project and figuring out the best approach of a dredging project to the selection of equipment and how to optimise the process of execution. Every dredging project faces it own set of challenges.

Maintenance dredging

A significant aspect of dredging is maintenance dredging. The water dept of port basins and waterways gradually decreases caused by tidal movements deposit sand and silt from the sea. Maintenance dredging is required to safeguard a constant navigable depth. How does maintenance dredging work and how to face the challenges?

Land reclamation

Industrial sites, residential areas, ports and airports are increasingly expanding in the direction of the water. Mainly driven by the exponential growth of the world’s population. Land reclamation is the dredging process of using sand, clay or rock from the seabed to create new land in coastal areas. How does land reclamation work?

IHC Dredging - Creating the maritime future

In the dredging industry, there is a significant journey ahead in moving to more sustainable solutions and durable operations. To prevent further damage to the environment and even reverse the damage done, focus is being put on topics such as emission reduction, creating a circular economy, climate neutrality and building an infrastructure to accommodate the energy transition towards renewables.

Craftsmanship since 1642

Dredging is in our DNA. With over 300 years of experience, IHC Dredging is the market leader for the design, build and delivery of reliable, integrated dredgers, equipment and services in the dredging sector. With knowledge built over centuries and through our passionate colleagues, we provide a competitive edge to our customers in the dredging industry worldwide.

Read more about the history of dredging

Download brochure IHC Dredging

How can we help you?

Get in touch and our dredging experts will help you.