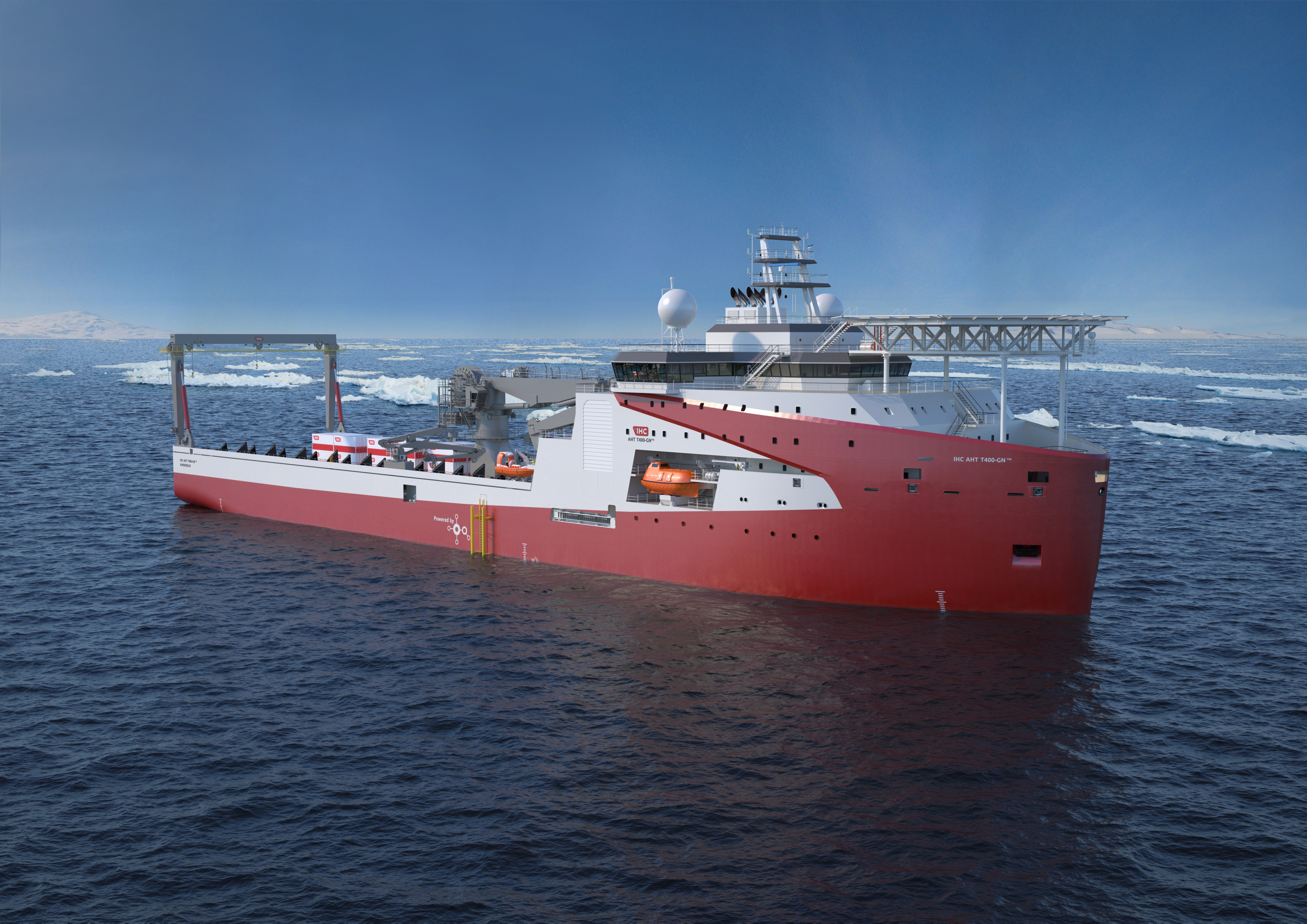

Anchor handling tug supply vessel (AHTS)

Our new class of anchor handling tug supply vessels (AHTS) facilitates efficient and sustainable infrastructure development for offshore wind farms. A purpose built, methanol fuelled AHTS vessel with optimised storage capacity, able to operate 24/7 in the harshest offshore environments.

Shorten installation times and reduce the number of vessels needed in the field, all while scaling up your commercial capabilities in the development of floating wind parks. With our methanol fuelled AHTS vessel you can lead the way in the energy transition.

AHTS vessels: fit for purpose design

In the life cycle of a floating wind farm an anchor handling and towing vessel is an essential asset. From assembly and installation to maintenance and decommissioning, an anchor handler tug will play an important part in the operation. Each stage in the development of floating wind farms requires assets with different characteristics. However, certain elements are the same such as reliability, storage capacity, safety and crew comfort. Next to an efficient operation and sustainable performance, these items are all reflected in our AHTS vessel designs, from small to medium, to large!

Environmental responsibility

Our AHTS vessels are ready to meet your needs for sustainable operations in wind farms with cost effective solutions. Net zero emissions at the wind farms are achieved by using a methanol battery hybrid power propulsion system. The vessels are methanol-ready from day one!

Our range of anchor handling tug support vessels

Having a range of three sizes for the AHTS vessels offers flexibility and adaptability for various operations. Introducing the options:

100t bollard pull

The smallest in our range of anchor handling tugs is perfect to tow – together with the T275- the floater to the site. Equipped with a 200t anchor handling winch it can also be used to retighten the mooring lines after a storm, for example.

275t bollard pull

The ‘medium sized’ AHTS vessel is designed for installation of infrastructure offshore, towing of Floating Offshore Wind Turbines (FOWT), and for handling anchors and mooring lines. It includes a DP class 2 capability, a 600t anchor handling/ towing winch and a 275t bollard pull. This next generation anchor handler can be used for towing and installation of FOWT’s on an industrial scale.

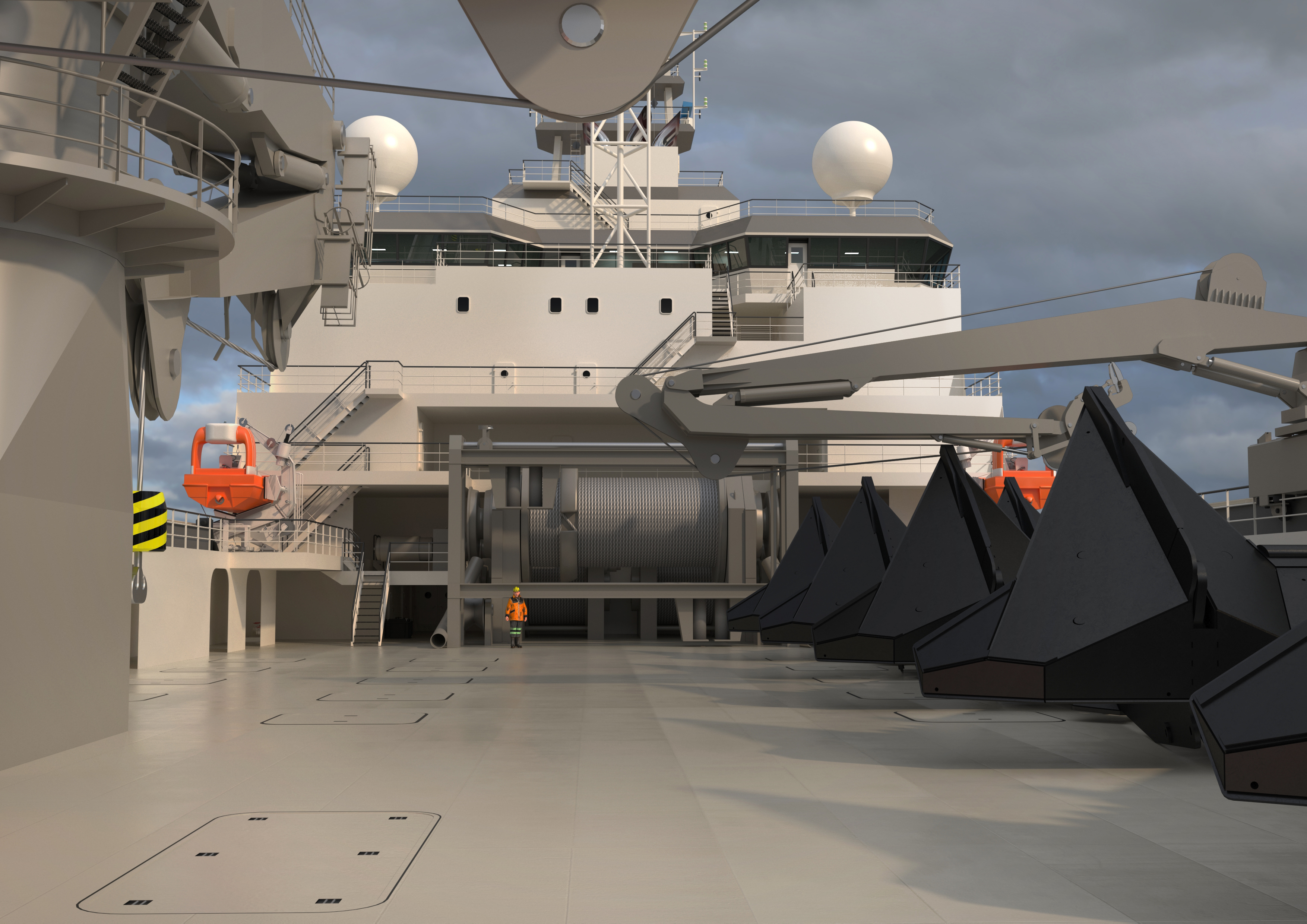

400t bollard pull

The biggest vessel in our class of AHTS vessels is designed with an anchor handling winch of 820 ton and a 400t bollard pull, making this a very efficient vessel for the deployment of anchors and mooring lines. A large work deck area and storage capacity offer you the full benefit of a high level of autonomy.

Key focus points in the development of AHTS vessels

The AHTS vessels are designed in line with Royal IHC's proven offshore hull design, characterised by good sea-keeping and crew comfort.

In the development of these vessels, key points are:

- crew and passengers safety

- environmental responsibility

- optimised hull and dynamic positioning performance

- operational effectiveness

- comfortable living and working environment

- high level of autonomy

The outcome is a robust and flexible design which can be fitted to your requirements for a bespoke technical solution.

An efficient and safe installation

Whether it is the anchor handler with a 100t, a 275t or a 400t bollard pull, you will benefit from a vessel with a specialist mission in mind. These anchor handling and towing vessels are based on our long-standing track record of designing and building class leading, complex, integrated DP vessels for the offshore industry. All of which has resulted in an asset that is not only very efficient, but also safe in operation.

- fit for purpose anchor handling system for catenary installation of offshore wind turbines

- optimised storage capacity for chains and mooring lines catering to majority of future offshore wind turbine designs

- battery assisted dual fuel hybrid power generation based on methanol

- designed to work safely in harsh and challenging offshore environments around the world

- accommodation able to facilitate a 24/7 work schedule

Scale up your commercial capabilities in the development of floating wind parks.

Let’s discuss what an AHTS can offer you.