Energy efficiency

Implementing efficiency improvement measures

In the transition towards zero emissions, Royal IHC’s activities centre on two pillars: energy efficiency improvements and cleaner fuels. While alternative fuels often need more storage space onboard a vessel, a way to reduce emissions and limit the required space for fuel storage is to implement efficiency improvement measures.

Fuel tool

To support this, Royal IHC has developed the Fuel Tool to assist designers in calculating the performance of a vessel’s drive system, fuel consumption and emissions. Onboard measurements can be combined to define an operational profile, permitting the most optimal drive system design to be selected.

Two-speed gearbox

Royal IHC has also developed a two-speed propulsion gearbox, which is beneficial for vessels that sail at lower speeds than their maximum design speed. While a vessel is sailing in a harbour for example, the gearbox can switch to another gear. On a typical dredge cycle, this is projected to lead to reductions in fuel consumption of 8-11%.

Optimised hull shapes

Hull shape is a significant design consideration and computational fluid dynamics (CFD) can help to optimise a ship’s hydrodynamic performance. At Royal IHC, we use our knowledge of existing vessel designs combined with detailed CFD calculations to analyse resistance and overall propulsion efficiency. This creates the basis for future innovations, leading to the development of increasingly fuel-efficient vessels.

Eco control

Royal IHC’s focus on innovation has resulted in the development of the Eco Control package. This makes use of three integrated controllers that manage a hopper dredger and its dredging process at a high level – a combined approach that minimises fuel consumption regardless of any disturbances acting on a ship. When tested on the DCI Dredge XXI for example, demonstrable fuel savings of 15% were achieved during operations.

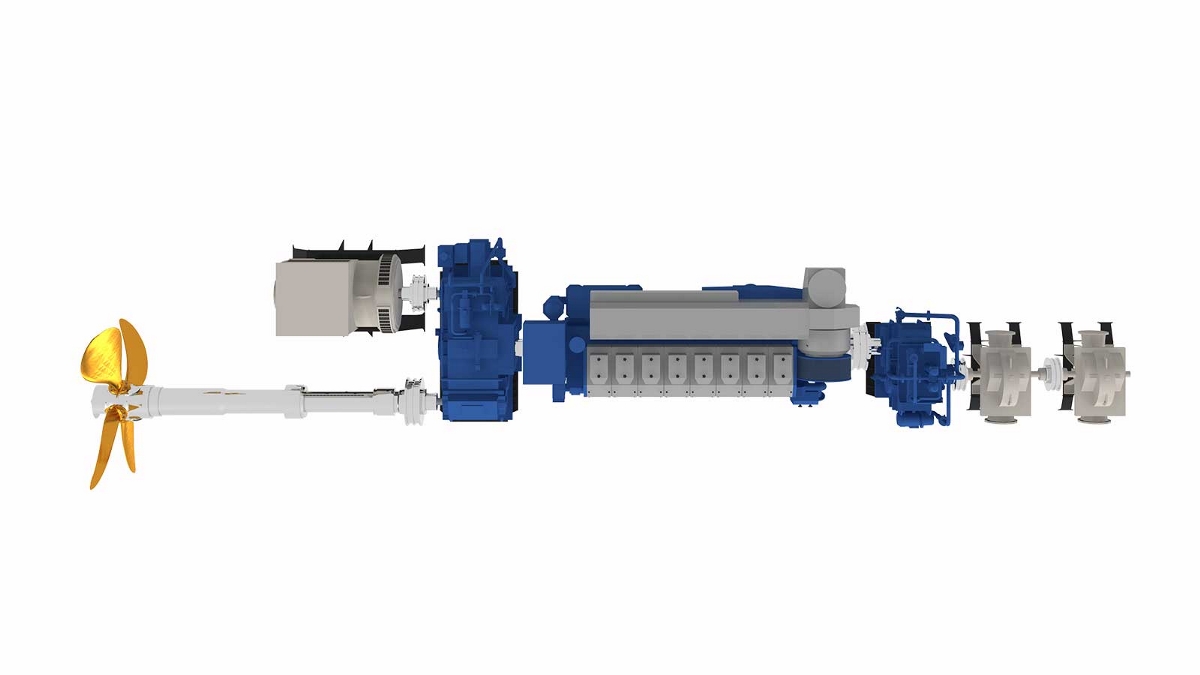

Waste heat recovery system

Having a diesel engine on board means that at least 50-65% of the energy generated by the engine is lost to the environment. With a waste-heat recovery system, there is an opportunity to reclaim a portion of that energy. It uses the heat of the exhaust to generate power and feed this back into the vessel. When used on the SPARTACUS, steam is transformed into electrical energy, contributing to a fuel efficiency improvement.

Stay up to date with the latest innovations

Wondering what we at Royal IHC are up to? Sign up for our newsletter where we highlight our latest innovations, new solutions and delve into market challenges.