Fuels and the transition to zero-emission vessels

Emission reduction is one of the biggest innovation challenges for the maritime industry. In recent years, this was mainly driven by the implementation of strict emission regulations, such as the IMO global sulphur limit.

As a result of the Paris Agreement, the focus is shifting towards the reduction of greenhouse gas emissions. This has started a transition towards zero-emission vessels, as conventional fossil fuels will be largely replaced by clean alternatives that are produced either from biomass or renewable energy.

Vessel concepts and tools for future-proof designs

But what is the impact of these challenges and what opportunities are there in the field of alternative fuels? In order to get a better understanding of these developments, Royal IHC has started a research and development project on zero-emission vessels.

Our focus is on where we can play a decisive role: the integration of alternative fuels and clean drive systems into complex work vessels. We are developing (near) zero-emission vessel concepts and create tools to optimise energy efficiency and emission reduction at an early design stage. With this knowledge, we can design vessels and solutions that best meet the needs of our customers.

Suitable alternatives

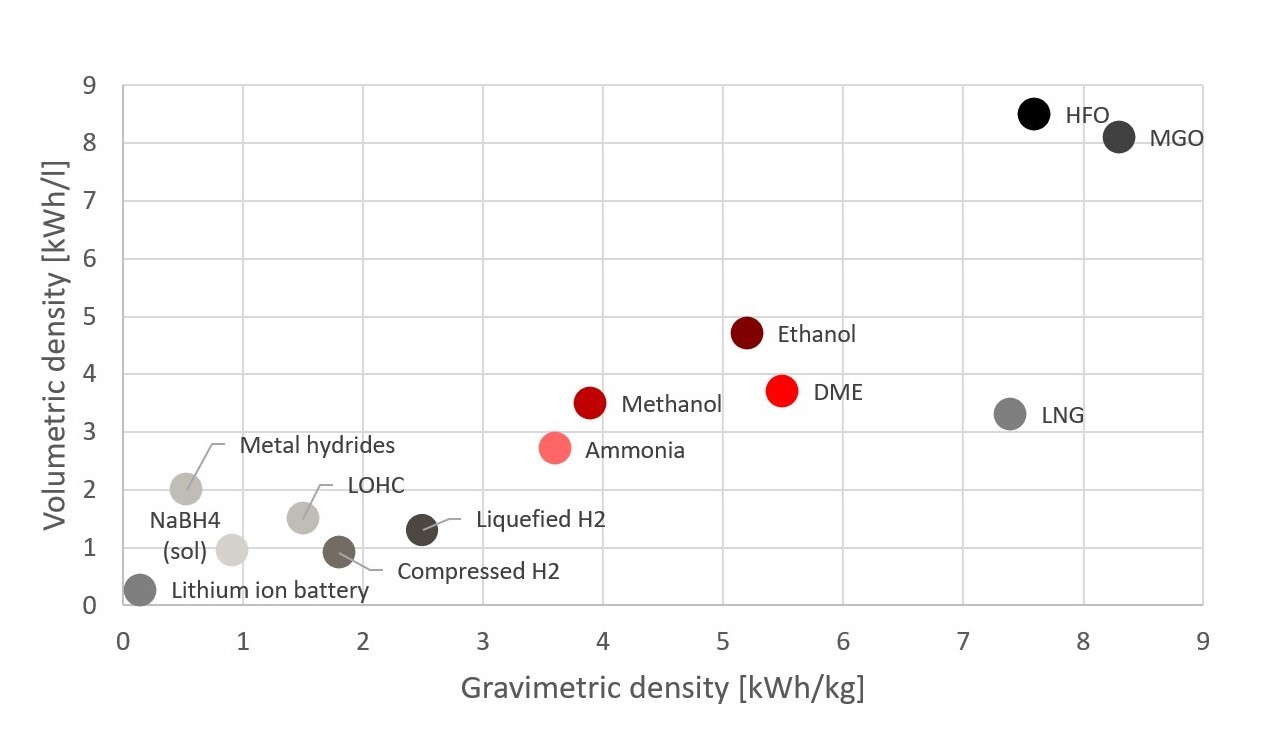

Several aspects come into play when looking at alternative fuels and how they can be integrated into vessels. One challenge in relation to vessel design is energy density. This is the amount of volume or weight that is needed to store a certain amount of energy.

Figure 1 shows the gravimetric and volumetric energy densities of several fuels. In this case, it includes the fuel storage system needed on board a vessel. It is clear from this figure that none of the alternative fuels can match conventional diesel on energy density. The required storage volume roughly doubles when diesel is substituted with methanol or LNG, and for the storage of hydrogen up to six times more volume is needed.

Figure 1: volumetric and gravimetric energy density of various fuels, including the onboard storage system.

Another important aspect is the availability of alternative fuels. In the short term, biofuels have the lowest impact on vessel design. However, it is questionable whether biofuels will become widely available for the maritime industry in the long term.

The most important limiting factor is the area of land required for biomass production. It is likely that other industries, such as chemical and aviation, will be willing to pay a higher price for carbon originating from biomass.

Green fuels produced from renewable electricity will be introduced to accomplish the energy transition. With this in mind, green hydrogen is considered to be the cornerstone of this transition, and green methanol and green ammonia are also promising candidates.

Looking to the future

A vessel’s operational profile and required autonomy determine the most suitable fuel. The low energy density of hydrogen is challenging for vessels with high power demands and a specific level of autonomy. Liquid fuels with a higher energy density, such as methanol and ammonia, are more practical in such cases. Hydrogen can be a preferred option if such limitations do not exist, for example when vessels operate close to shore or have plenty of space for fuel storage.

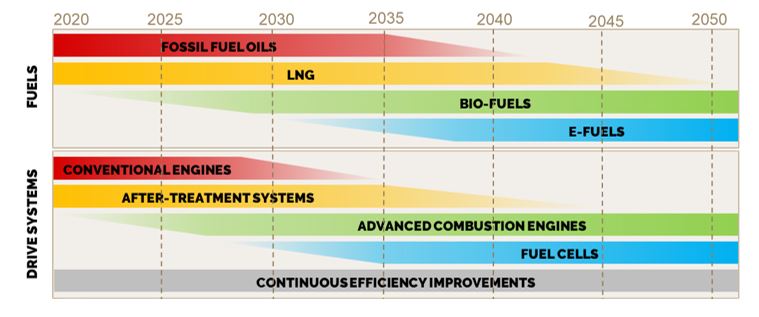

Although it is hard to predict the future, we have defined our expectations in figure 2, based on our expert knowledge.

Figure 2: IHC's expectation on alternative fuels and alternative drive systems for complex work vessels.

LNG is a clean fossil fuel, but will be phased out due to its limited CO2 reduction potential. Biofuels are also available, but their potential is expected to be limited in the long term. Eventually, fuels produced from renewable electricity will take over. Although it might seem that these fuels will only emerge in ten years’ time, we expect to see demonstrations of e-fuel applications in the coming years.

The transition towards zero emissions will not only affect the choice of fuel, but also the types of drive systems. Conventional engines will be replaced by advanced combustion engines and fuel cells, and drive trains will increasingly be electrified. In our next blog, we will explore the anticipated developments in drive systems.

Written by

Erik van der Blom

Innovation manager vessels

Want to learn more about the transition to zero-emission?

Fill in the form and one of our experts will tell you.