Is there a future for internal combustion engines?

In previous blogs, we wrote about the innovative and complex drive systems that are required for the maritime energy transition. Fuel cells were mentioned as the prime mover for the future and yet, you may wonder if internal combustion engines still have a role in future drive systems?

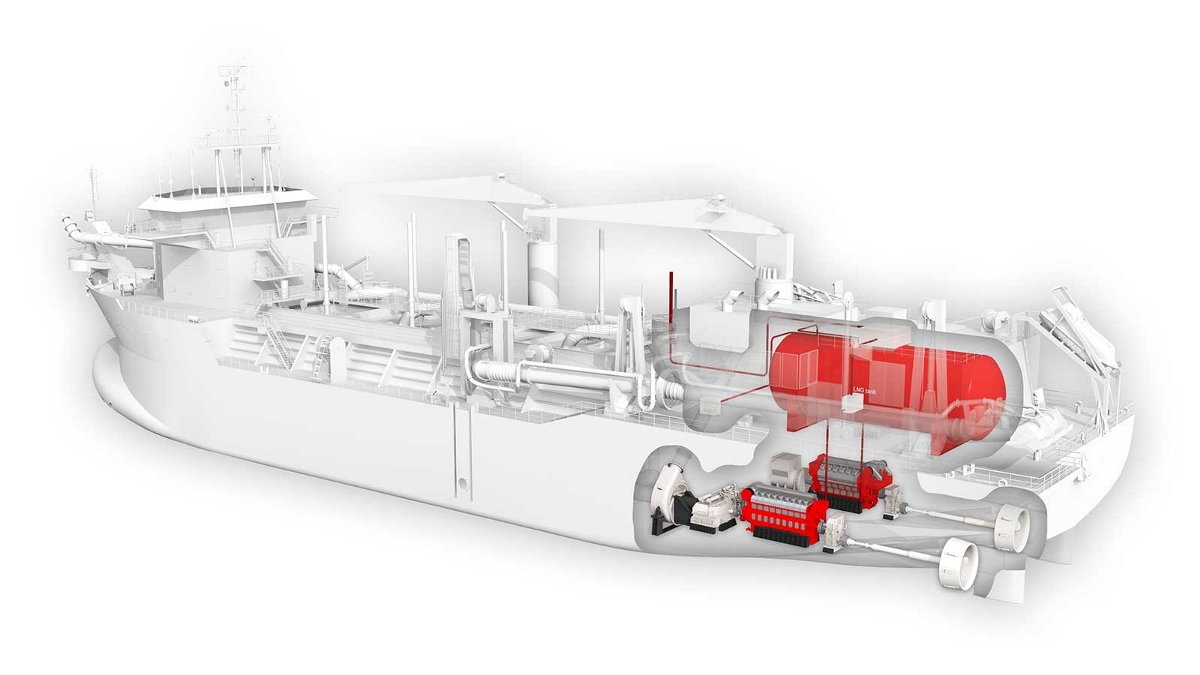

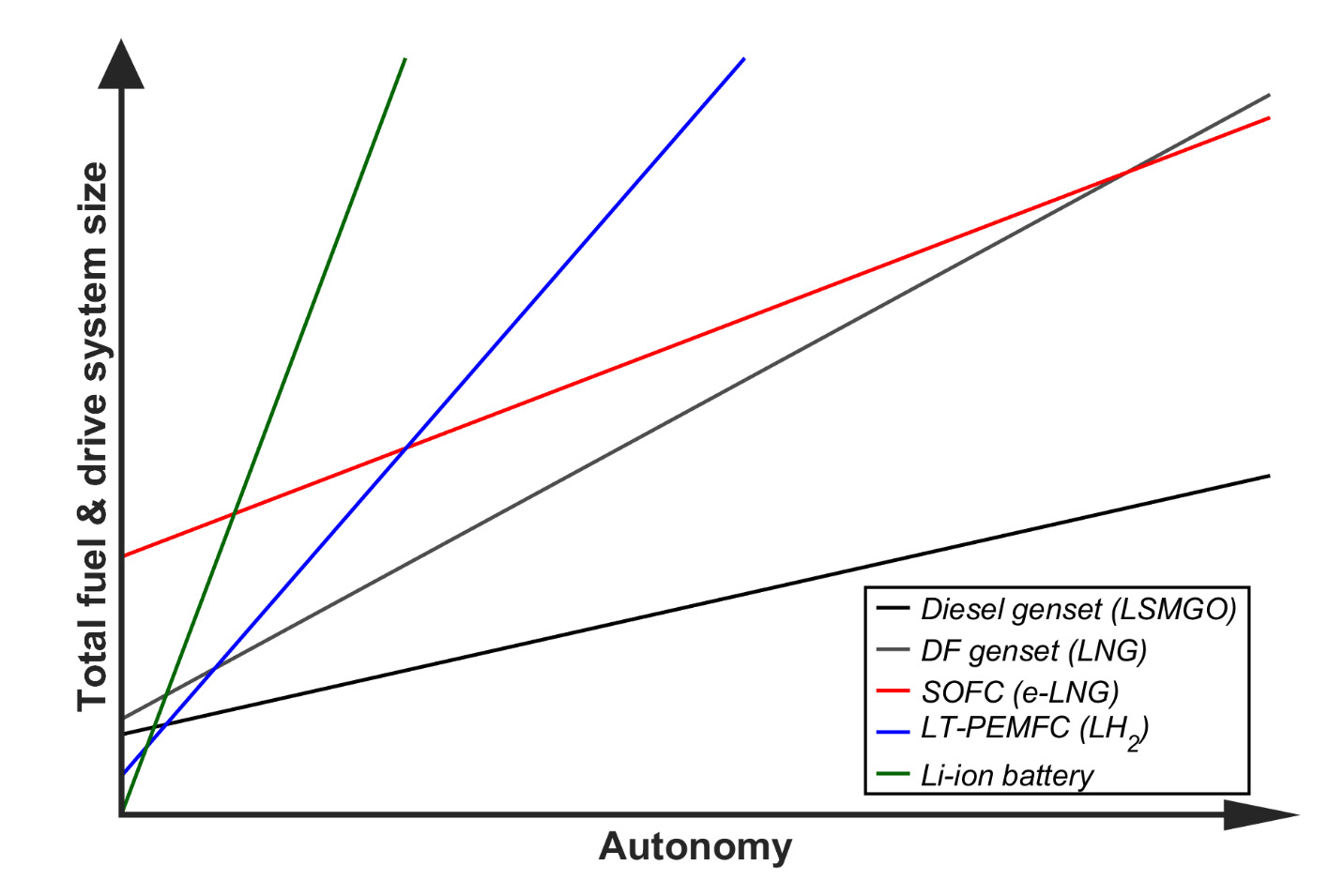

For me, the answer is “yes”. At Royal IHC, we think that internal combustion engines will continue to have a role to play in the maritime energy transition. In the short term, internal combustion engines will still power all larger ocean-going vessels. At the moment, only some vessels with very specific operational profiles and work areas may be fully powered by batteries or hydrogen-fuelled fuel cells (see figure 1).

Ocean-going vessels require more energy-dense hydrocarbon fuels and/or ammonia, and the maritime solid oxide fuel cells (SOFCs) required for these fuels are still in development. This is the gap in which the internal combustion engine can show its potential until SOFCs – or other more efficient prime movers – become available.

Figure 1: Indicative total fuel and drive system size versus vessel autonomy.

Figure 1: Indicative total fuel and drive system size versus vessel autonomy.

Dual fuel (DF) engines

The recent uptake of liquefied natural gas (LNG) necessitated the application of DF engines. When these engines operate in gas mode, it results in a significant reduction of the nitrogen oxide (NOX) emissions. In turn, lower emissions have a positive impact on the air quality in coastal areas and near harbours.

The DF engine concept could also be applied in the future to other renewable fuels, such as hydrogen or e-methane. This makes the DF engine a ‘fuel flexible’ power generation solution, capable of adapting to several types of new fuels. It is expected that LNG will be the most suitable fuel for the next 20 years, until one or more renewable alternatives are available to fuel the maritime sector. And so, the DF engine looks set to be the prime mover of choice for the coming years.

Gas-diesel (GD) engines

However, existing DF engines are limited to fuels with a high Octane number (the indication of a fuel’s ‘knock resistance’), such as methane and hydrogen. Combusting other fuels, such as ammonia and methanol with (near) zero emissions, requires new developments.

The GD engine is capable of combusting methanol and other fuels in a Diesel-like process, such as on the STENA GERMANICA. However, this process is not able to achieve the low NOX emissions of the DF engine, regardless of the applied fuel. Therefore, additional measures, such as water injection or the application of exhaust gas after treatment, are required.

New engines based on the GD concept are currently in development and may be ready for application in five years. Manufacturers are approaching the construction of engines in a more modular way, allowing for the conversion of a new diesel or DF engine into a GD engine with limited effort.

Advanced combustion engines

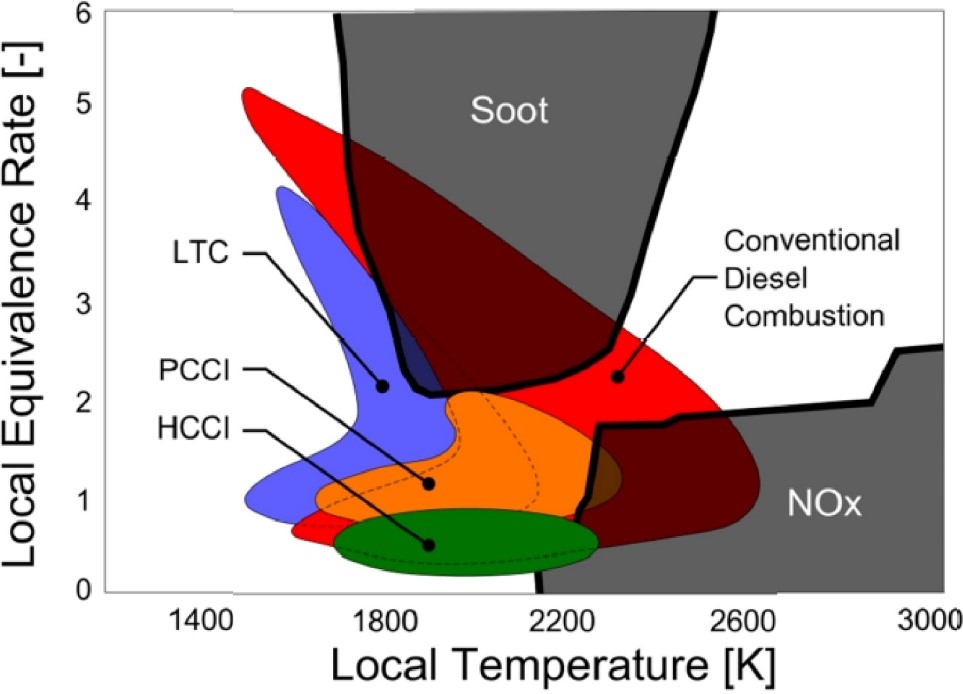

An engine with the potential to produce lower emissions is the reactivity-controlled compression ignition (RCCI) engine. This has the ability to control the combustion process with more precision, resulting in a high efficiency, and lower NOX and soot emissions (see figure 2).

The RCCI engine promises a low emission combustion process for low reactivity fuels such as methanol, without the need for additional measures. However, it is currently in development and a time to market is not yet known. Alongside the RCCI engine, there are other concepts in development, including two-stage turbocharging and hybrid electric turbochargers.

Figure 2: Regions of NOX and soot formation with several compression ignition engine types, such as conventional diesel combustion, homogeneous charge compression ignition (HCCI), premixed charge compression ignition (PCCI) and l ow temperature combustion (LTC) (Agarwal et al., 2017)

Figure 2: Regions of NOX and soot formation with several compression ignition engine types, such as conventional diesel combustion, homogeneous charge compression ignition (HCCI), premixed charge compression ignition (PCCI) and l ow temperature combustion (LTC) (Agarwal et al., 2017)

Summary

The table below contains an overview of the above-mentioned prime movers and two main fuel cell types. The DF engine in combination with LNG seems to be the preferred low (harmful) emission solution for vessels with a high power requirement and a large autonomy for the coming 10 to 20 years.

For vessels operating close to the coast or inland, and therefore requiring a short autonomy, a hydrogen fuel cell system and/or a battery electric system is the most likely candidate.

| Diesel engine | DF engine | GD engine | RCCI | SOFC | LT-PEMFC | |

| Emission reduction potential (NOX & PM) | Low (after treatment required) | High | Medium (after treatment required) | High | >99% | >99% |

| Fuel flexibility | Only diesel (incl. bio- & synthetic) & DME | Medium (high Octane number) | High | High | Sulphur-free fuels | Only pure hydrogen |

| Efficiency | <> | 45-50% | <> | 45-55% | 50-60% | 45-55% |

| Time to market (MW scale) | Now | Now | ± 5 years | > 10 years | 5-10 years | <1-3> |

| Modularity prime mover | Low | Medium | Medium | Medium | High | High |

| Power density | High | Medium | Medium | Medium | Low (future: medium) | High |

Figure 3: Overview of prime mover options.

Our role

IHC is actively participating in national and international research projects, such as JOULES, ShipDrive, GasDrive, Green Maritime Methanol, NEON and Zero JIP . We do this to gain knowledge, contribute our know-how and stimulate new developments. In combination, this helps us to provide the most optimal long-term solution for our customers. If you are interested in collaborating with us in this field, we look forward to hearing from you.

Written by

Benny Mestemaker

Senior research engineer New Fuels & Drive systems

Stay up to date with the latest innovations

Wondering what we at Royal IHC are up to? Sign up for our newsletter where we highlight our latest innovations, new solutions and delve into market challenges.