Shaking tables

Shaking tables in short

We manufacture a complete range of tables to suit all requirements from small laboratory models through to the large process models. Feed capacities can be accommodated from 25 kg per hour to 5,700 kg per hour and can accommodate a wide range of particle sizes.

Why choose our equipment?

- highest particle separation efficiency in the market

- wide range of feed capacities

- various riffle patterns to suit a wide range of particle sizes

- can be outfitted with high-efficiency motors.

Wilfley Tables

The Wilfley Table has been manufactured in Australia for over 100 years and our table still retains many of the original design features incorporated into the original tables by Arthur Redman Wilfley. There are other so-called Wilfley Tables, but their design is far different to the original designs and operational criteria.

With over 2,200 tables now manufactured, the Australian Wilfley Table is the most recognised brand of table available in the market. A major part of our business is the rebuilding or refurbishment of tables, not only the Wilfley Brand but also all other makes and models. We specialise in new decks as well as deck rebuilds. Refurbished motion boxes are also a common requirement. We also have a large range of fully refurbished tables in stock and are ready for sale.

Application

The following are a few of the operations in the art of concentration in which our Wilfley Concentrating Table can be used:

- before or after floatation units for the recovery of coarse mineral not readily recovered by floatation

- as pilot tables following floatation machines to serve as an indicator to the operator of the efficiency of each machine and for the recovery of valuable minerals when the floatation unit is not working at a point of high recovery. Wilfley Tables used as a pilot table give the operator instant warning of inefficient operation and serve as a safeguard against heavy tailings loss

- for two or more mineral separations from floatation concentrates, previous table middlings or from original feed

- for efficient concentration of low-grade mineral feeds to produce a high-grade concentrate for metallurgical treatment and tailings to waste

- for concentrating a middling feed producing a high-grade concentrate and a middling for regrinding

- for the concentrating of mineral feeds of low specific gravity such as graphite, molybdenum etc.

- for the recovery of metallics etc. from free gold ores, refuse in brass foundries, cyanide plants, assay offices, re-melting and casting works and jewellery shops

- as a means of controlling classification in milling plants under certain conditions

- for washing and cleaning inferior coals, iron ore etc.

Table sizes and types

Sizes and types of the various Wilfley Tables are shown in the data table. The standard deck covering is marine plywood with sugar-pine or maple riffles and finished with multiple coats of wear and water-resistant urethane epoxy paint.

| Capacity in kg per hr/table | 25 | 50 | 75 | 100 | 250 | 400 | 600 | 1000 | 1500 | 2000 | 3000 | 4500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| #13 standard lab table | Y | Y | Y | |||||||||

| #13 oversize lab table | Y | Y | Y | |||||||||

| #12 half size table | Y | Y | Y | |||||||||

| #9 three quarter size table | Y | Y | Y | |||||||||

| Single deck, full size table | Y | Y | Y | |||||||||

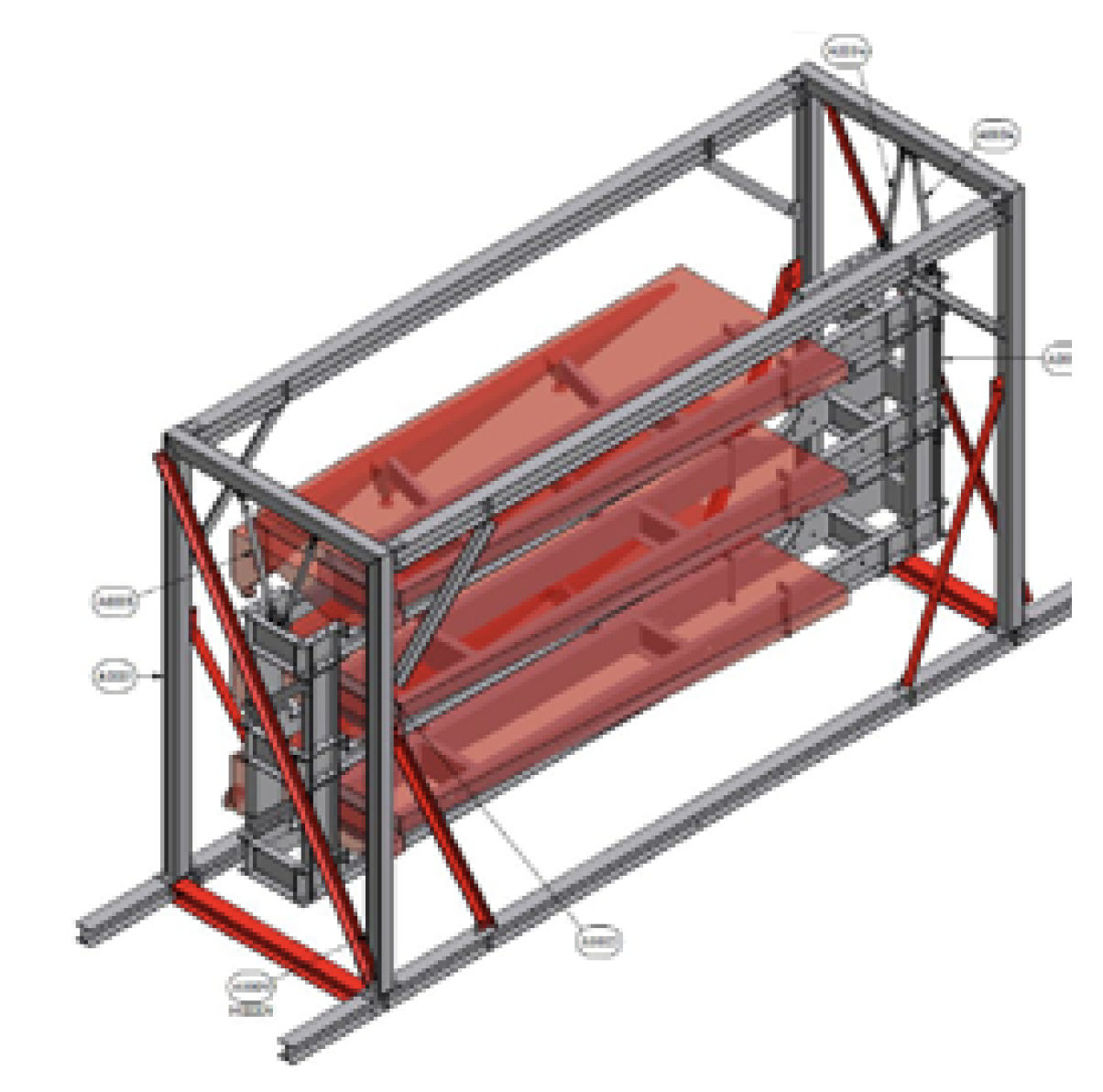

| Double deck, full size tabe | Y | Y | Y | |||||||||

| Triple deck, full size table | Y | Y | Y |

Downloads

More information?

-

Brian

RodriguesGeneral Manager IHC Mining Australia

How can we help you?

Looking for advice on our shaking tables? Fill in the form and our experts will help you.