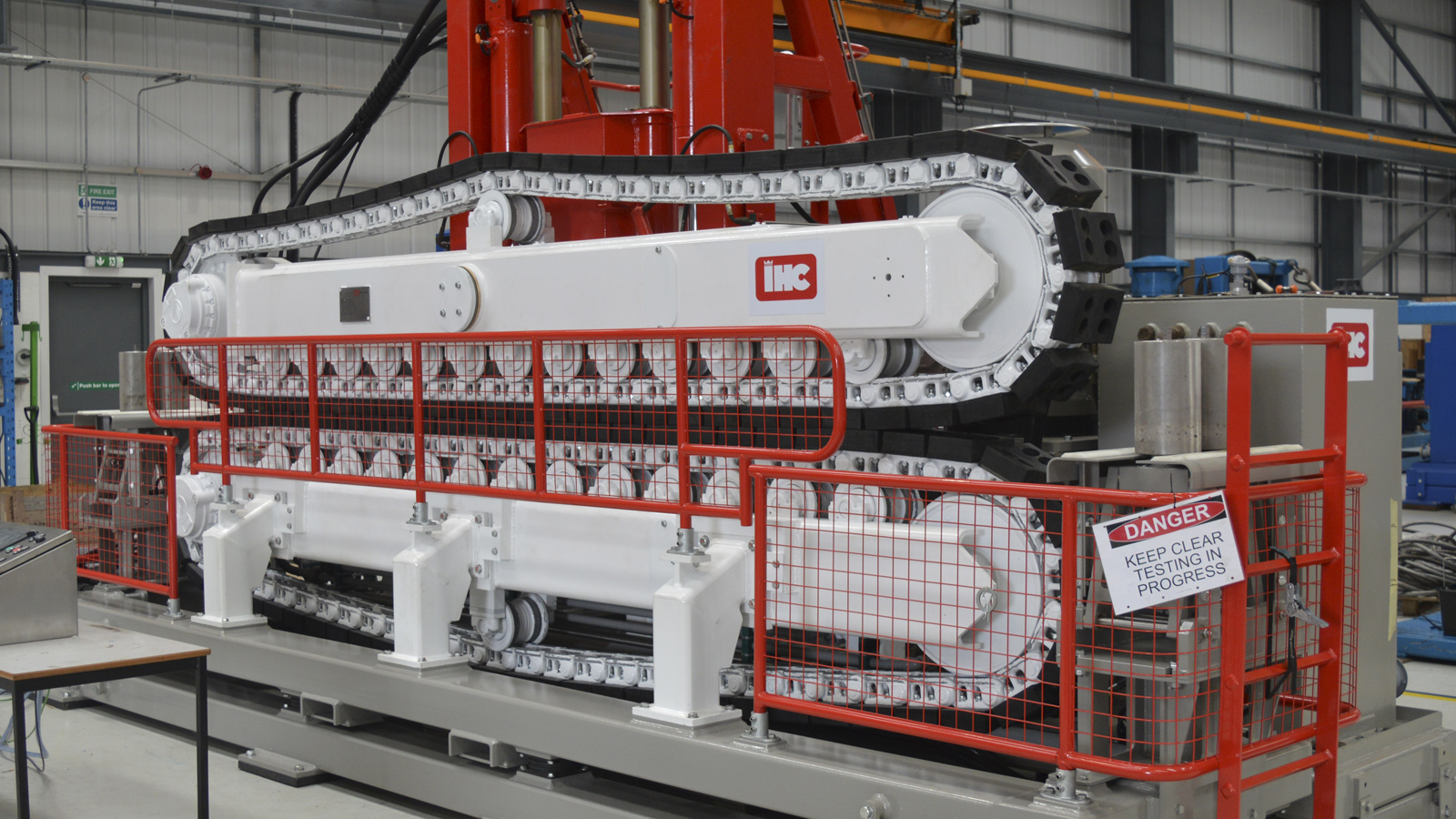

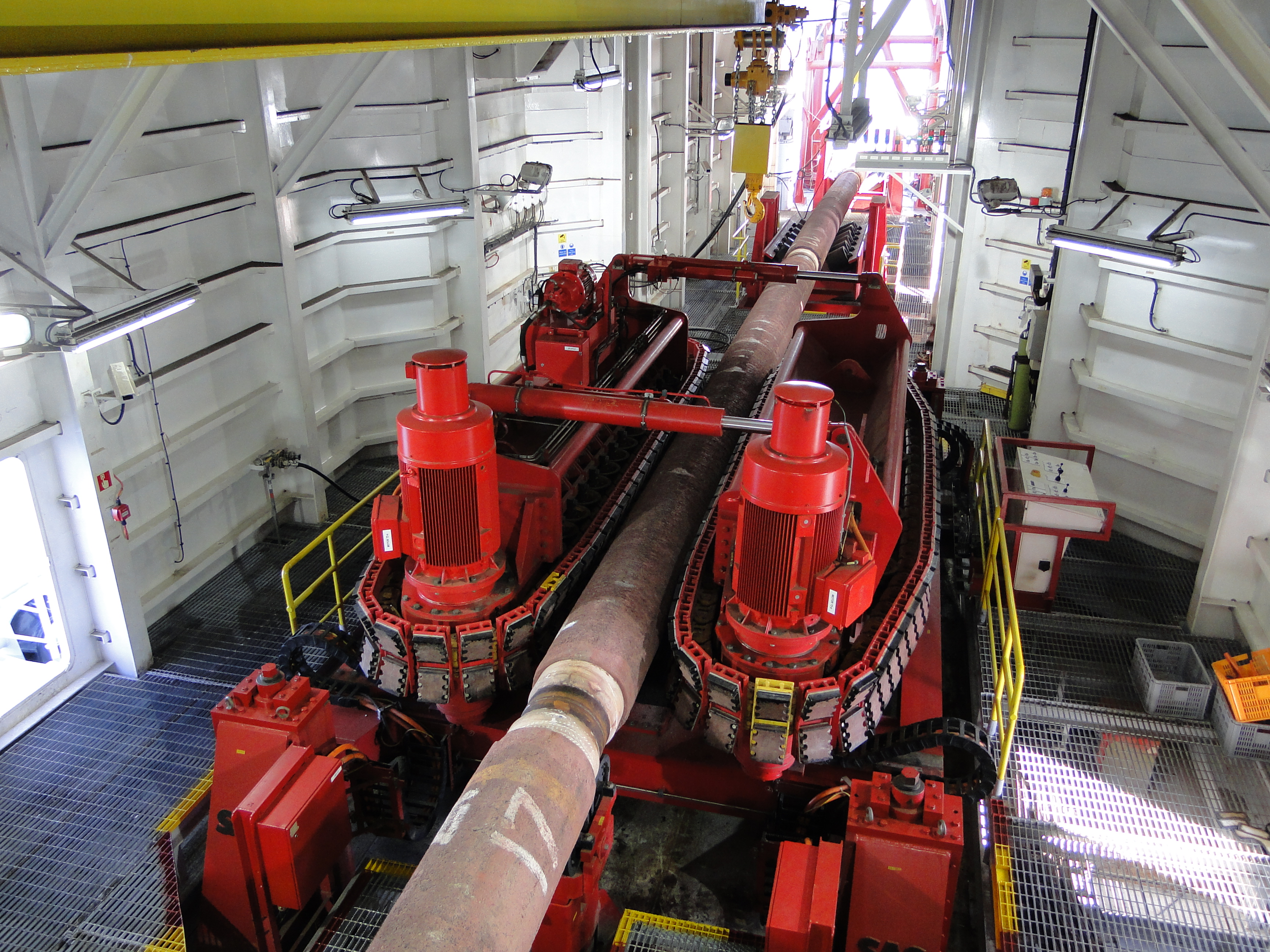

Pipelay tensioners

2-track and 4-track Tensioners

We design and deliver SAS® 2-track tensioners in both horizontal and vertical track configurations mainly for S-Lay applications. Furthermore we design and deliver 4-track tensioners for both horizontal and vertical lay systems mainly for laying flexible pipe and reeled rigid pipe. Our range of tensioners is ideal for flexible or rigid (coated) pipe- or cable-laying operations. All our tensioner systems are supplied with a highly sophisticated and user friendly control system, in-house developed ever since our first tensioner delivery back in the seventies.

Tensioner product range

We provide following tensioner types:

- 2- track horizontal S-lay tensioners

- 2-track vertical S-lay tensioners

- 2-track spooling tensioners

- 2-track tensioners for cable lay

- 4-track tensioners

- Wheel pair tensioners

- 3-track spooling tensioners.

Advantages

- extensive knowledge in pad materials and friction coefficients due to extensive R&D program

- accurate active clamping control is standard

- impressive track record

- global after sales network

- ability to deliver completely integrated pipelay systems even including vessel new build.

Tailored to your requirements

Our tensioners can be tailored to meet your specific requirements, including variables such as friction coefficients, squeeze force and contact length. Our tensioners have the unique capability to adjust track body position while clamping the product, and to accurately maintain pipe tension.

Features

- adjustable suspension with large stroke on S-lay tensioners

- tensioner range from 15t to 500t

- sliding pads possible on large size S-Lay tensioners

- unique horizontal track orientation in 2-track tensioners allows concrete dust to fall between the chains and not on the chains

- robust and maintenance friendly design

- clamping always perpendicular onto the product. This results in accurate clamping control

- highly sophisticated tension control system

- energy efficient solutions by using active front end drives to re-use generated power during pipelay operations

- Fully automatic load transfer from tensioners to A&R winches and vice versa

More information?

-

Erik

HoogakkerSenior sales manager

Your tailored tensioner system

Our experts enjoy thinking along with you