Zero emission SOVs: the need for renewable offshore wind operations

The road to a zero-emission economy requires renewable energy sources, and offshore wind has emerged as one of the main prospects for green energy in coastal countries. The first offshore wind farms were built near the shore, and were easily accessible for maintenance activities with small crew transfer vessels. New farms will be located further offshore, resulting in longer transit times and thus requiring a dedicated service operating vessel (SOV).

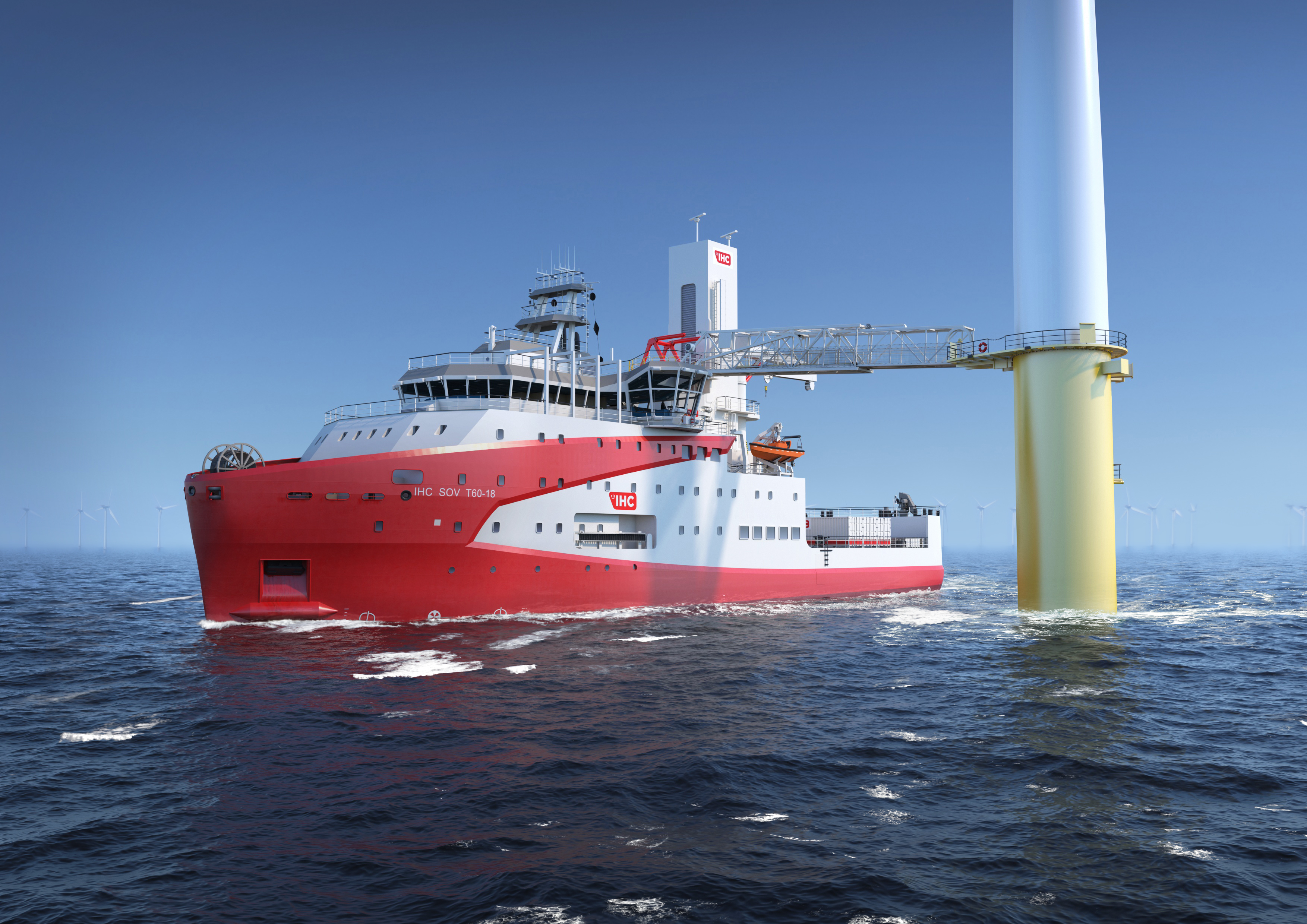

The life-cycle emissions of offshore wind energy are lower than those of fossil fuels. However, emissions still occur owing to the maintenance vessel. Royal IHC has been developing zero-emission concepts for several vessel types (from dredging to offshore) to eliminate the emissions of high-end complex vessels. In this innovation blog, I would like to focus on our zero-emission concept: the SOV T60-18.

A holistic approach

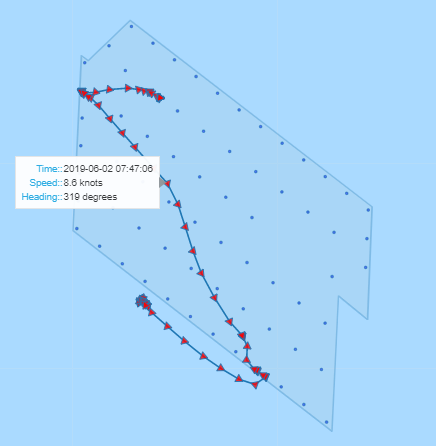

The power generation system of the T60-18 has been designed around its operational profile to maximise emission reduction potential. Valuable insights regarding the current application and possible improvements to the vessel have been gained by analysing the operational data of various SOVs in the North Sea.

Determining operational profile by means of long-term SOV vessel positioning analysis

Determining operational profile by means of long-term SOV vessel positioning analysis

A holistic approach is required to integrate alternative fuels and innovative drive systems in the T60-18, and in our previous blogs of Erik van der Blom and Bernardete Goncalves Castro we assessed alternative fuels and drive trains when compared to conventional units.

Many alternative fuels have a lower energy density. This means that conventional autonomy requirements of 30+ days cannot always be achieved without increasing the vessel size to accommodate fuel storage. However, from the operational profile analysis, we found that a bunkering interval of every 14 days would align with the current SOV operation.

With the input from fuel suppliers, drive system and tank manufacturers, vessel operators and owners, and classification societies, we are developing innovative zero-emission SOV concepts. Several potential ‘future fuels’ and drive-train systems have been considered in developing the T60-18, such as compressed and liquefied hydrogen, methanol, ammonia and dimethyl ether (DME).

However, each concept presents its own unique challenges with respect to safety (toxicity to humans, explosion risks, fuel handling etc.) or harmful greenhouse gas emissions.

Liquefied hydrogen as an energy carrier

As an example, I would like to highlight the liquefied hydrogen concept of the T60-18. Depending on the shore-based infrastructure, liquefied hydrogen could be a potential energy carrier. Low temperature proton exchange membrane fuel cells would be the preferred prime mover, because they have a higher efficiency than internal combustion engines and require less fuel.

The T60-18 has also been designed to offer sufficient space below deck to store liquefied hydrogen for the required autonomy without affecting the warehouse capacity or accommodation areas.

A projection of liquefied hydrogen and LT-PEM fuel cells on board the T60-18

A projection of liquefied hydrogen and LT-PEM fuel cells on board the T60-18

Hybridisation of the SOV drive system with a (temporary) energy storage system is required for most alternative fuels. An energy storage system allows the SOV to be operated while fully electrified for a certain period of time. This acts as the required spinning reserve for dynamic positioning (DP) operations and can facilitate peak shaving. In this way, low-load engine operations, running hours and fuel consumption are reduced.

The journey towards zero emissions

Other interesting advances in this field include ‘mission master’ developments. This covers autonomous operations, path planning and dynamic positioning; creating an intelligent ecosystem that optimises the activities of the T60-18. To fully utilise the potential of an SOV, all developments should be effectively integrated, including fuel, hybridisation and smart operations.

Zero-emission concepts for various types of vessels are at the core of Royal IHC’s innovation activities. Now, the question is not if, but when we will be ready for the next step on the road to a zero-emission economy. Regardless, Royal IHC is ready to cooperate with all stakeholders in the maritime industry, such as vessel owners and operators, in order to co-design and optimise such concepts to their individual needs.

Written by:

Jan Westhoeve

R&D Engineer

Get in touch

Curious what zero emissions concepts are available to you? Ask one of our specialists.