Top loading plough

Superior ground penetration and stability

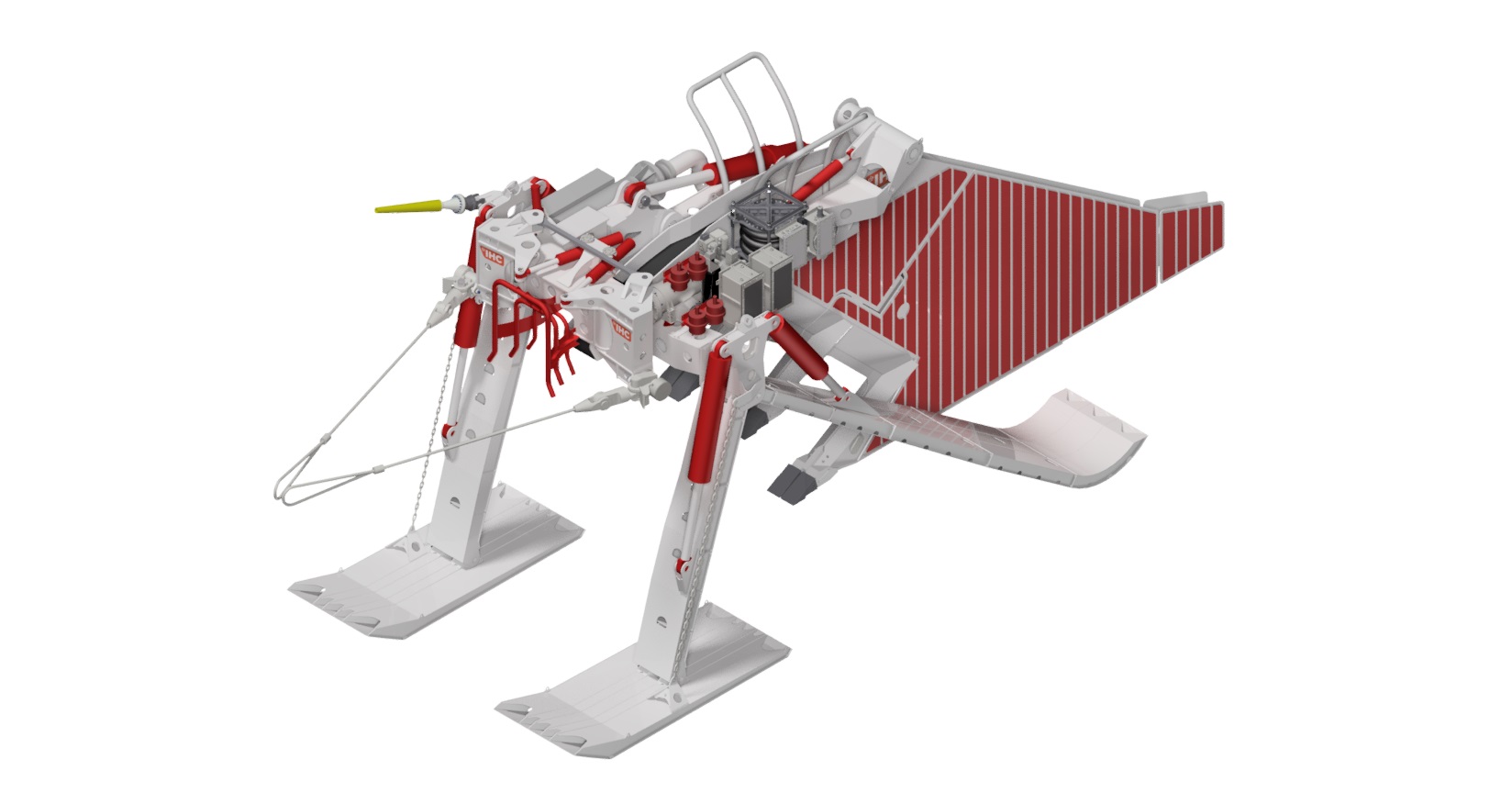

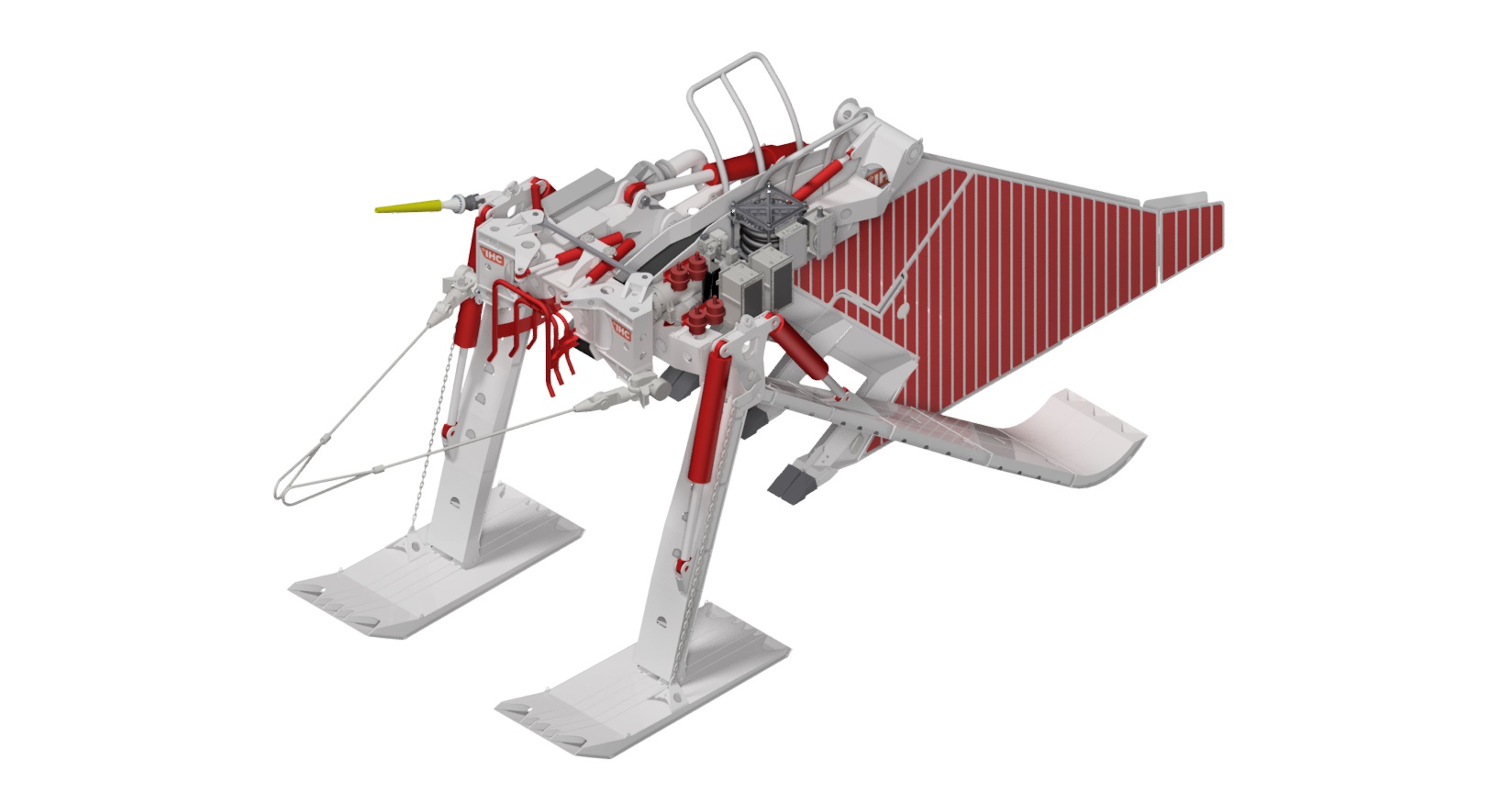

The plough comes complete with Royal IHCs 2.3m or 3.5m aggressive forecutter share which provides superior ground penetration and stability for a given tow load, thereby reducing ongoing fuel costs. The raked profile of the share also prevents the plough from ‘riding out’ during operations which other third party wedge type shares have a tendency to do.

Secure operations

Our patented top loading design enables the product to be directly loaded into the plough, after it has been lowered to the seabed, thereby eliminating the risk of compromising the product MBR, or having to undertake sensitive handling operations. The bellmouth, drawbar and depressor are manoeuvred out the product pathway to allow the product to be laid, with the aid of guides, into the plough.

Easy user configuration

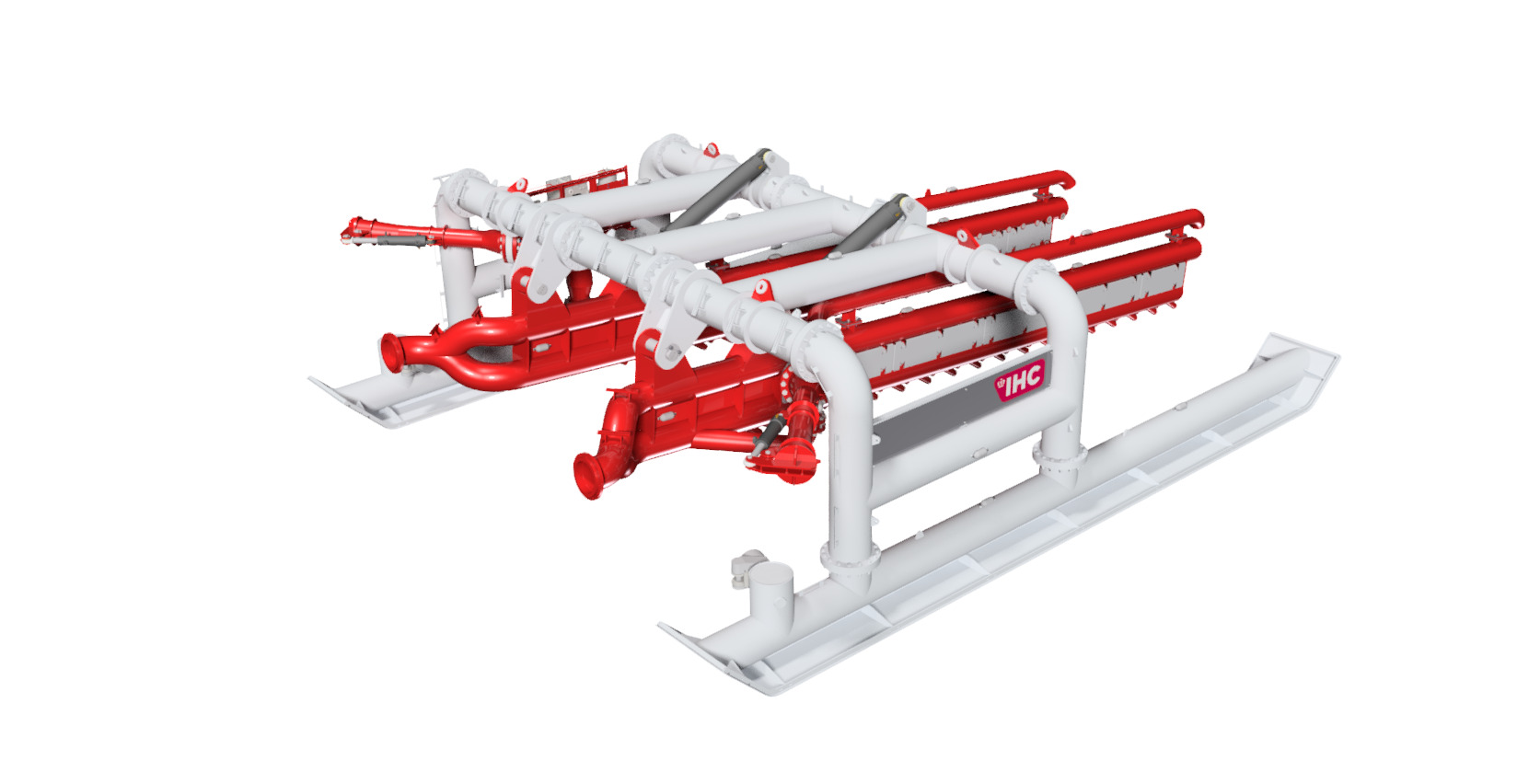

Up to 600kW of jetting can be integrated seamlessly into the share. Nozzle positions, pump pressures and flows can be easily user configured allowing operators to optimise the jetting system to suit project specific soil conditions for either sands or clays thereby maximising trenching speeds.

Features

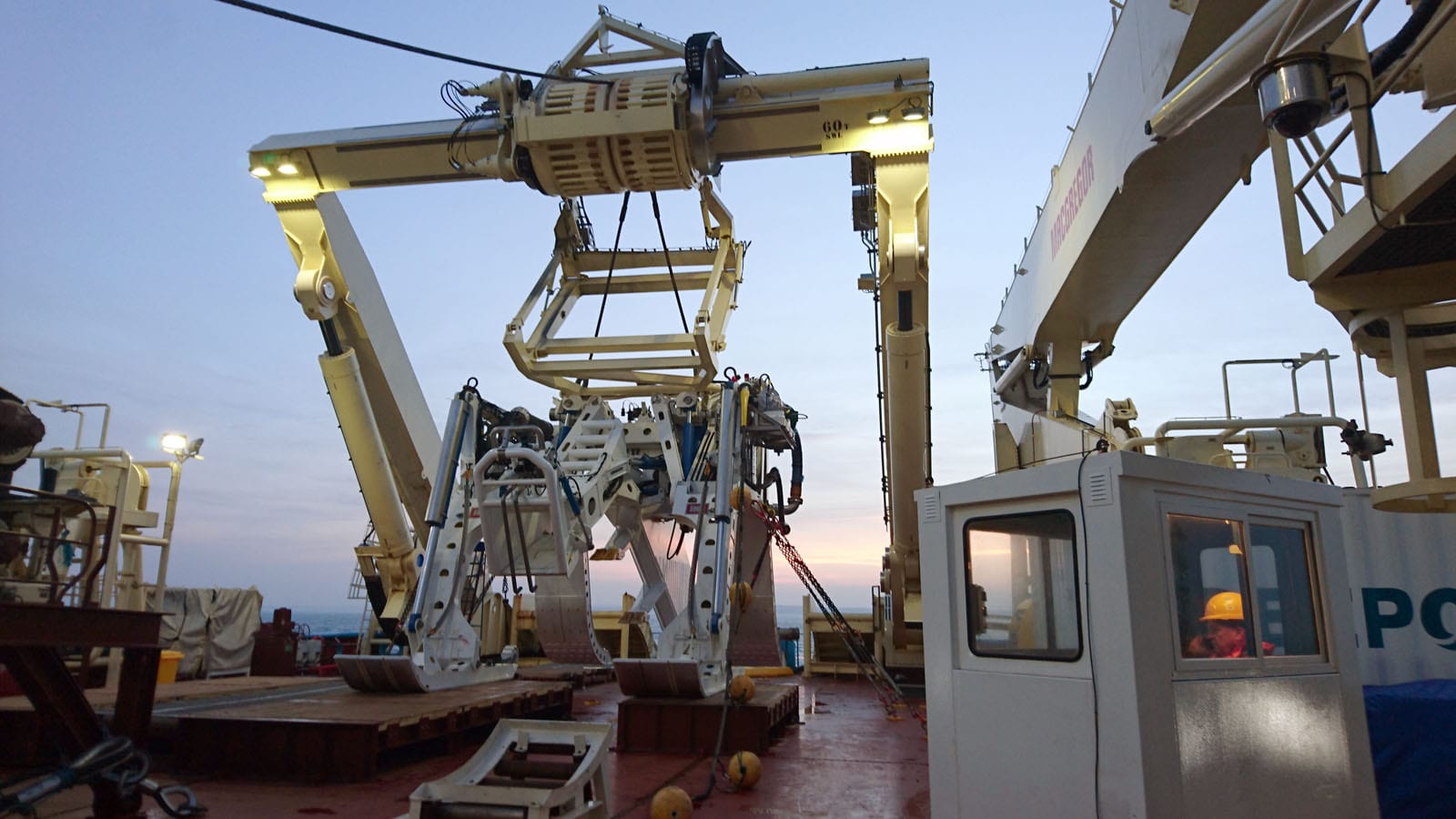

- patent pending top loading plough design keeping the plow light. This allows for launch/recovery and towing using a single winch and rope, reducing the cost of the associated LARS. Reduced weight means more tow load goes into trenching than overcoming frictional losses, making the plough more efficient and therefore reducing vessel fuel costs

- design uses a patent pending plough simplification. The patent removes the need for a bell mouth/chassis hinge by using longer skid arms and stabilisers to better control the grade in process and provides the following benefits: removing functions required by competitor offerings and maintaining high stability during operation

- the 6kV jetting umbilical reduces power losses during transmission, reduces cost and weight of umbilical and associated components and improves efficiency and therefore reducing vessel fuel costs

- improved share, the raked share providing improved capability over the vertical knife shares of competitors. Share extensions to provide optimal project trenching configurations, reduced cost of ploughing operations

- proven share jetting system. Can be launched with a wide angled A-frame allowing the use of a combined lift/ tow winch, negating the need for separate lift and tow winches. No requirement to undock and redock the plough during deployment or recovery.

Specifications

|

Description |

Specification |

|

Water Depth |

0 to 2,000m Rated (Operation limited by Tow Rope and Umbilical Length) |

|

Trench Depth |

Standard Configuration: 0 to 2.3m (0o aft pitch) |

|

Soil Strength |

5kPa (minimal skid sinkage) |

|

Weight in Air |

Approximately 42t |

|

Dimensions (2.3m Share) |

Length: 13.3 m (skids down) Height: 4.5m (drawbar down) Width: 5.4 m (over stabilisers) |

|

Max. Tow Force |

150t peak force |

|

Cable |

Product Path 430mm Minimum to suit: Ø10-400mm diameter cable |

|

Cable Min. Bend Radius (MBR) |

5m (bellmouth, share and depressor) |

|

Wear Parts |

Replaceable and widely available cutting tips Abrasion resistant material on cutting blades and sides of share Wear plates on cable route including bellmouth, share and depressor |

|

Plough Handling |

Tow rope handling with tow bridles suitable for cable ship A-frame and stabilising frame |

|

Steering |

±15° |

|

Working Seabed Slopes (typical) |

≤12° downslope, ≤14° upslope, or ≤6° side slope |

More information?

-

Robert

HaylockSales manager subsea vehicles and launch & recovery systems

Can we be of service?

Our experts are happy to give you advice.