Decarbonizing cable lay vessels with LNG

LNG as transition fuel

The transition to a climate-neutral society requires that we move away from fossil-based fuels, something still prevalent in the maritime industry as a whole, and look to more renewable energy sources. That being said, offshore wind has proven to be a main prospect for green energy especially in coastal countries.

Seeing as wind farms generate renewable energy it is only fitting that the vessels at work in these wind farms also do not impact the environment. Traditionally powered by fossil-based fuels, we are seeing a shift such as that towards LNG. Seen by many as a transition fuel, being true for fossil natural gas.

Transitioning to LNG

With LNG being predominantly methane, it has the lowest carbon emission per unit of energy of all hydrocarbon and alcohol-based fuels. The origin is currently mostly fossil-based, but it may also be produced from biomass (liquefied biogas) and/or from renewable hydrogen combined with captured carbon dioxide (liquid synthetic gas). Where fossil-based LNG is unacceptable in the long term, we predict that LBG (liquefied biogas) and LSG (liquefied synthetic gas) will have a larger share of the gas mix. Synthetic gas can be produced with the methanation of green hydrogen combined with CO2 from carbon capturing, and more efficient technologies such as co-electrolysis are under development.

Reducing NOx and solving methane slip

In combination with an internal combustion engine, LNG gives a significant reduction of nitrogen oxide (NOx), sulfur oxide (SOx), and particulate matter (PM) emissions, about 85%, 99%, and 95%, when compared to diesel. Despite these significant reductions, methane slip could diminish the greenhouse gas (GHG) emissions reduction on a life-cycle basis depending on the applied engine technology. Methane slip can be solved by selecting Solid Oxide Fuel Cell (SOFC) technology as the prime mover.

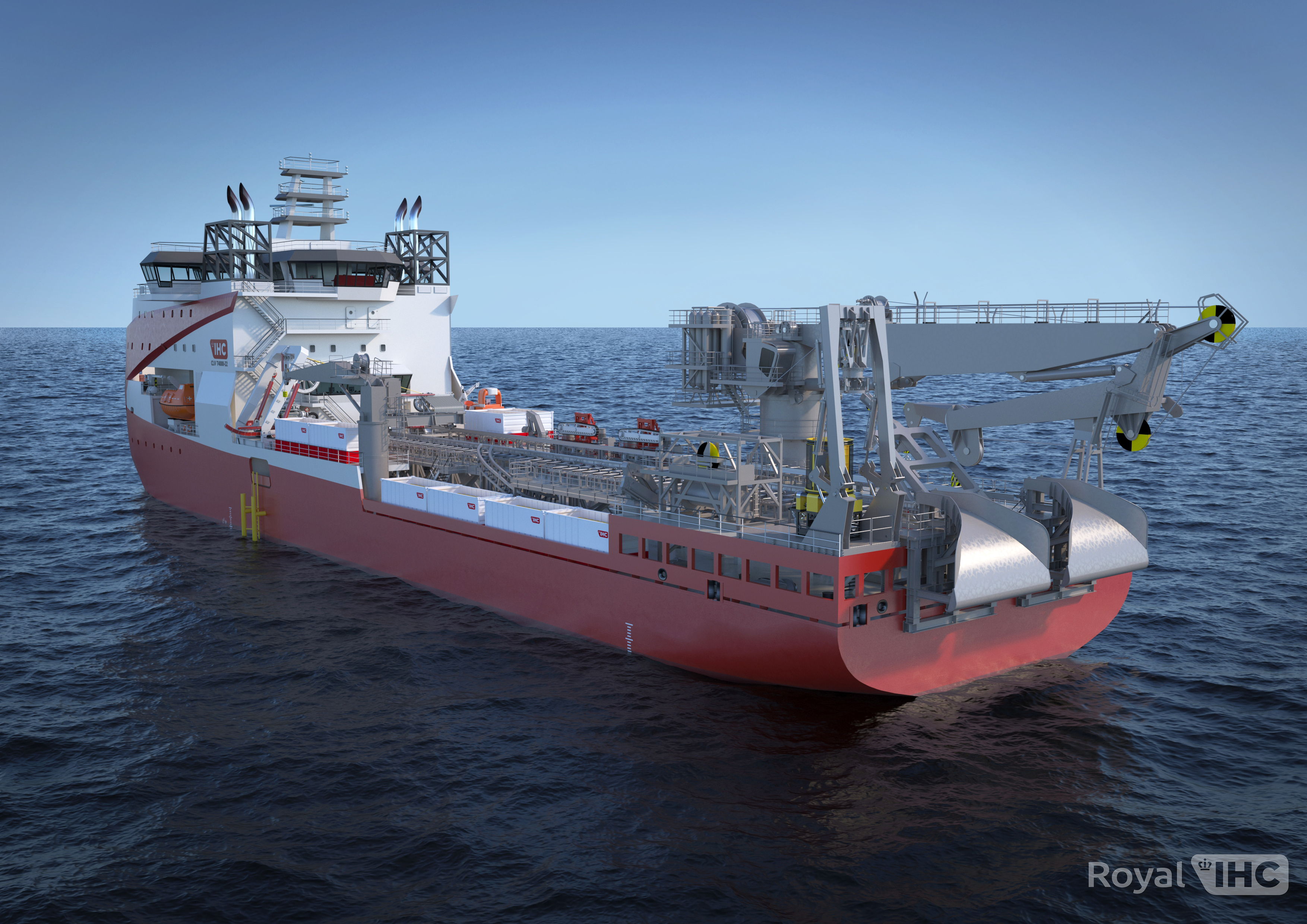

Integrating LNG into our Cable Lay Vessel design

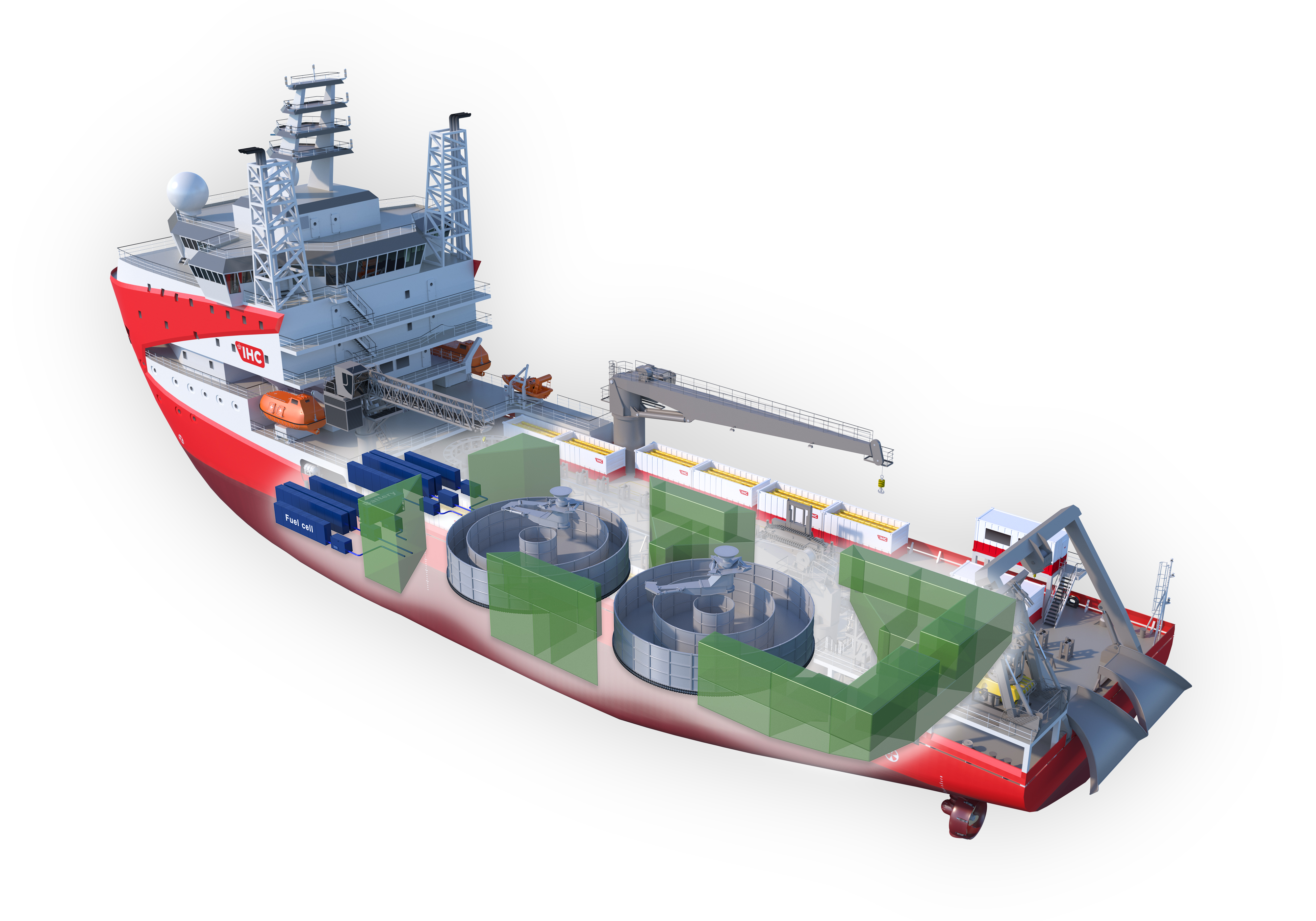

Liquefied natural gas (LNG) can be integrated into our cable lay vessel design, enabling the decarbonization process of the offshore fleet in the upcoming decade. Our inter-array CLV lays power cables between wind turbines in offshore wind farms, being equipped for this purpose with a total capacity of 4000 ton cable payload in two under-deck basket carousels. The LNG-fueled CLV concept is designed for an autonomy of 30 days. That being said, LNG cannot be stored in the ship construction tanks like methanol or diesel.

By placing a vertical LNG bi-lobe tank and two fuel cell rooms between the accommodation area and the carousels, as presented in the artist impression, it is possible to integrate the LNG fuel storage and prime mover. A battery room is placed adjacent to the thruster room to deal with dynamic power variations belonging to the vessel’s operation and operating limitations of the fuel cells.

Readiness of marine systems and fuel availability

Currently, some barriers limit the availability and operation of this concept CLV. Sufficient power density, costs, and the durability of the SOFC technology are the primary barriers. The power density defines the dimensions of the fuel cell room and thereby possibly having impact on the vessel size. High energy efficiencies make fuel cells very attractive compared to conventional / internal combustion engine technology, though the capacities of fuel cells cannot cover all maritime applications. The SOFC operates at high temperatures (500-1000°C) allowing for fuel reforming in the fuel cell and with enough waste heat for an external reformer if required.

The operating conditions of these fuel cells require a steady-state operation, which is challenging in relation to the power variations of these work vessels. Research is currently ongoing worldwide to make the SOFC commercially viable for maritime application in the coming decade.

More alternative fueled vessel concepts

Royal IHC is taking the development of more alternative fueled vessel concepts further to find the most efficient and sustainable solutions for our customers. This LNG fueled inter-array cable lay vessel with solid oxide fuel cells is an example of this as it shows how emissions can be reduced, though effort is required to develop these systems towards commercially-off-the-shelf products.

Related

Get in touch

Our specialists are happy to help!