Methanol-fueled cable lay vessels

Improving sustainable performance with methanol-fueled cable lay vessels

The first offshore wind farms were built near the shore, and were easily accessible for maintenance activities with small crew transfer vessels. Developments see new farms located further offshore, which in turn results in longer transit times. Where wind farms are seen as a renewable energy source it is strange to think that the vessels used for maintenance of these farms would only further impact them.

Enter alternative fuel sources. Similar to the transition from fossil-based fuels to LNG, another alternative exists when exploring opportunities for more sustainable fuel solutions. That of methanol. And like LNG, Methanol can provide an answer to reducing emissions and the overall environmental impact of the SOV's at work within offshore wind farms.

Why methanol?

Methanol (or to give it its chemical formula: CH3OH), is expected to be one of the fuels in the renewable fuel mix for the transportation sector along with several other energy carriers such as hydrogen, methane and ammonia. It is liquid at room temperature and ambient pressure, and has a volumetric energy density similar to that of liquefied natural gas (LNG). These properties make methanol a feasible option as an alternative maritime fuel, because the handling and storage of methanol is much simpler than cryogenic fuels such as LNG and liquefied hydrogen.

Safety

However, specific precautions must be taken when handling methanol. It is a light, volatile, colourless and flammable liquid with a distinctive odour. Even though it is non-toxic to aquatic life, it does have a low acute toxicity. This means that it is toxic for humans if swallowed, inhaled or it comes into contact with skin. IMO is developing design rules for methanol as part of the IGF code.

Limited availability of green methanol

Green methanol, such as bio-methanol and e-methanol, significantly reduce CO2 emissions by about 85%, however production volumes are still limited. In the future, green methanol may be produced from a wide variety of feed stocks and through different pathways. This and methanol’s worldwide availability and distribution network make it a promising alternative for conventional fuels.

Maritime four-stroke engines capable of operating cleanly and efficiently on methanol are still in development. Methanol can be combusted in Otto combustion engines with either a (diesel) pilot fuel or spark to ignite the air-fuel mixture. It can also be used directly in high-temperature fuel cells, such as solid oxide fuel cells and molten carbonate fuel cells. Some low-temperature fuel cells – such as direct methanol fuel cells and high-temperature polymer electrolyte membrane fuel cells with proper pre-reforming can also operate on methanol. The STENA GERMANICA is currently the only methanol-fuelled vessel with a customised gas-diesel engine. Off-the-shelf maritime four-stroke engines are currently not available. Royal IHC actively participated in the Green Maritime Methanol project which ran for two years during 2019 and 2020, investigating the application of methanol as an energy carrier for shipping by studying technical and operational effects, the economic and environmental viability, and how these impact different shipping applications. Read about the results here.

Feasible alternative without affecting the purpose of the vessel

Let’s focus on the potential for methanol in the offshore market, and in particular, inter-array cable-lay vessels (CLVs). In ambient conditions, methanol takes liquid form. It requires the same volume of storage space as LNG (when including the storage systems) and can be integrated in bunker tanks in a ship’s structure. This makes methanol a feasible alternative fuel for complex working vessels without heavily affecting the purpose of a CLV.

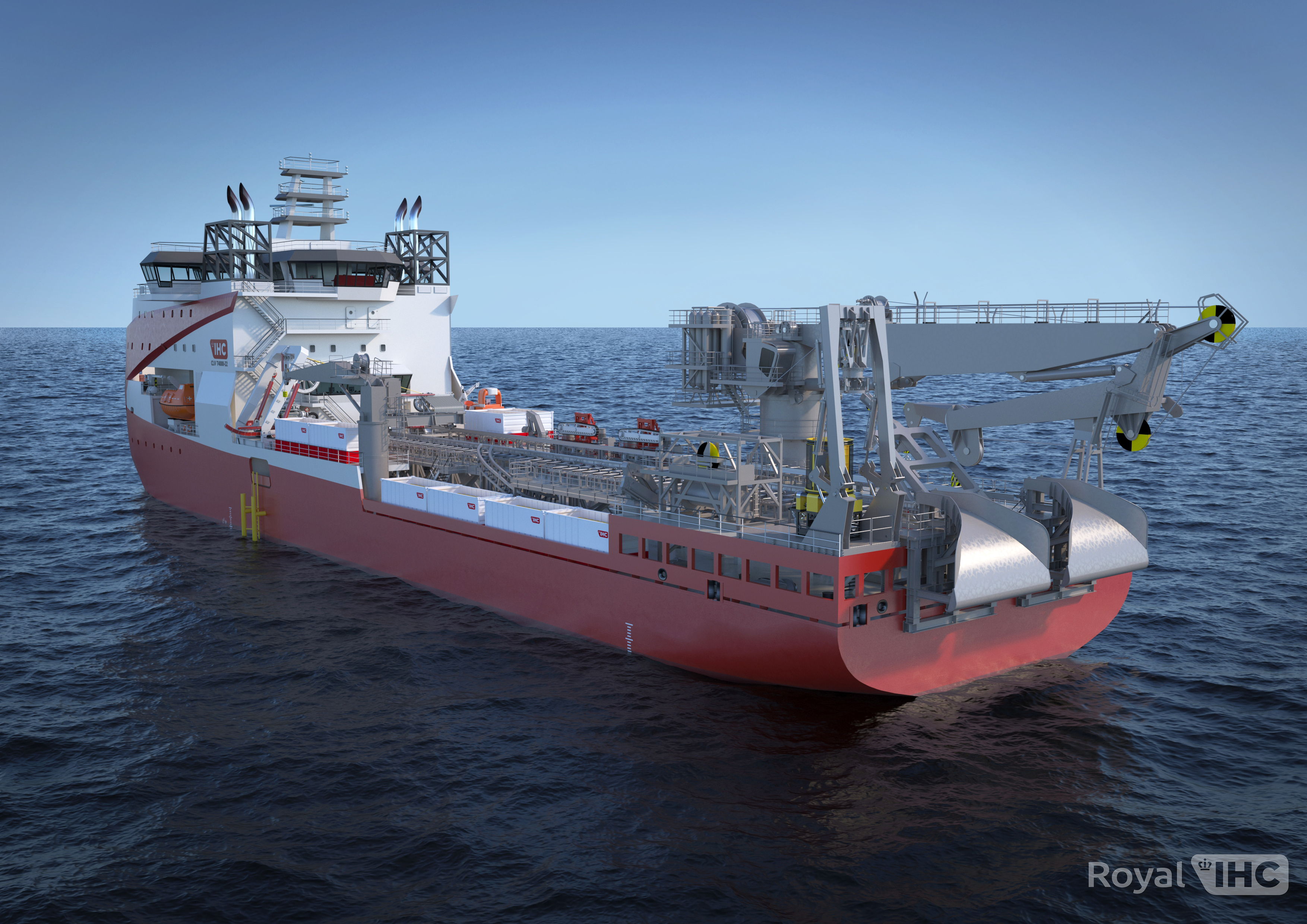

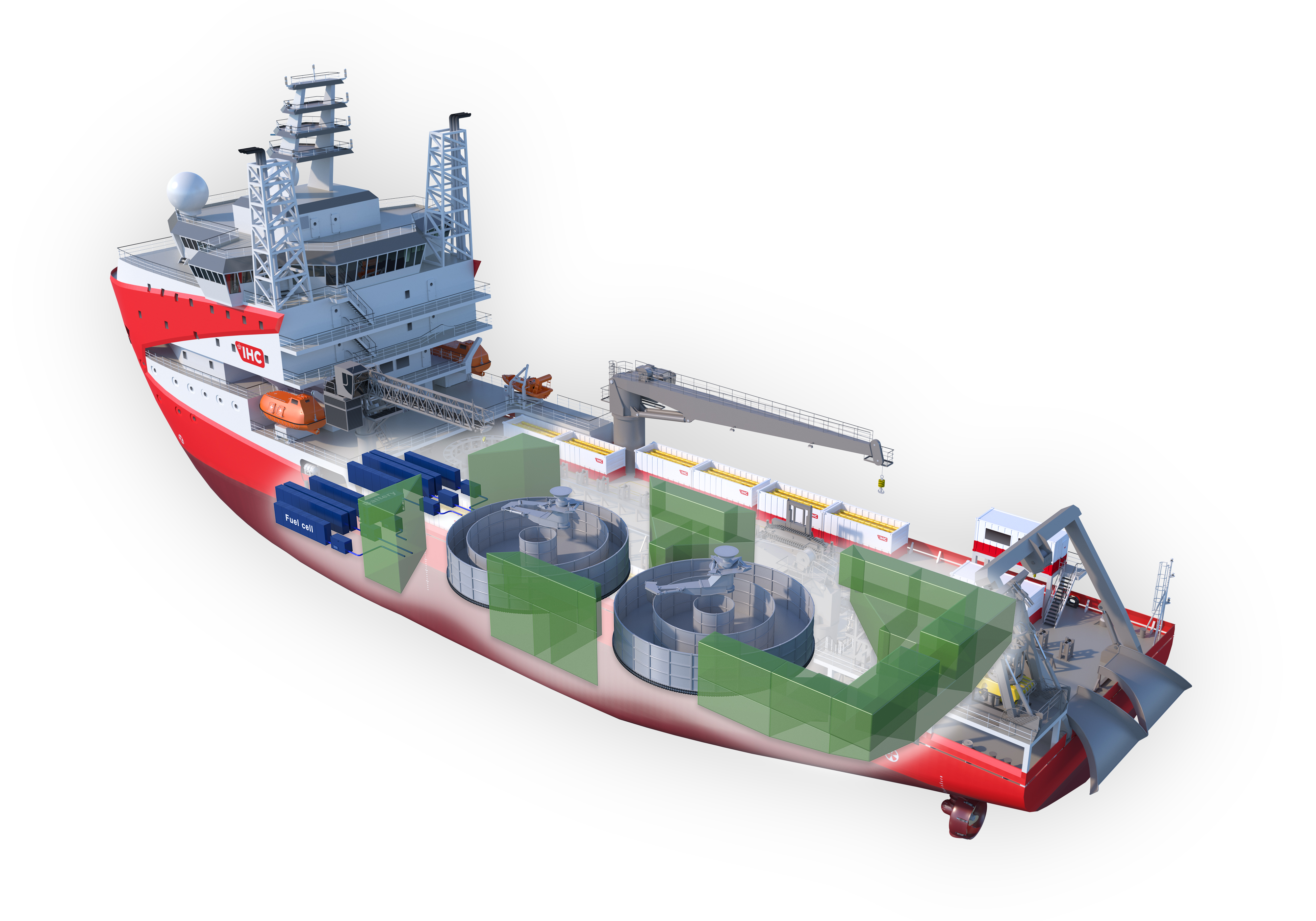

Methanol-fueled inter-array CLV

One of the vessels now fueled by methanol is the IHC inter-array CLV (IHC iCLV4000-22). The IHC inter-array CLV has a total capacity of 4000t cable payload with two under-deck basket carousels. The smart routing of the cable offers the flexibility to lay cable over the port or starboard side and allows for simultaneous cable loading. The storage of the carousels below deck leaves ample deck space to store containers and a 50m quadrant track. This results in a fit-for-purpose vessel with full integration of IHC’s cable-lay equipment and the vessel design. If we compare the concept design of this vessel with a conventional one based on marine diesel, it clearly shows that full functionality, autonomy and dimensions are sustained.

30-day autonomy

The methanol-fueled IHC inter-array CLV is designed to maintain autonomy for 30 days without increasing the vessel size. The general arrangement offers sufficient space below the deck to accommodate the fuel storage tanks. This ensures the required autonomy and an optimal operation, without affecting the cable-lay equipment arrangement or the accommodation areas.

IMO Compliance

Moreover, safety precautions have been considered during the development of the design, which complies with the official rules and amendments of the IMO on low-flashpoint fuels. Complying with these codes and following the alternative design route will lead to equivalent levels of safety for the crew and the overall operation (when using alternative fuels compared to conventional fuels).

Continued zero-emission development

Zero-emission concepts for various vessel types are a fundamental element of Royal IHC’s sustainable performance activities. Driven by innovation, we are actively cooperating with different stakeholders in the maritime industry to provide the most efficient and sustainable solutions for our customers. We’d like to hear from you if you want to join us on this journey and find out more about our developments in methanol-fueled CLVs.

Related

Get in touch

Our specialists are pleased to provide more information.