Value of data in dredging operations

In today's digital age, data has emerged as the lifeblood of industries worldwide, revolutionizing the way businesses operate and make informed decisions. The dredging industry is no exception. In fact, data holds immense potential to enhance your dredging operations, optimise efficiency, and drive sustainable outcomes. In this article, we discuss the added value of data-driven decisions in the dredging industry.

Performance and profitability

Data plays a vital role in project planning and execution of dredging activities. After winning a dredging project tender, the execution of the dredging plan is critical to achieving profitability. You want to be sure that your assets are making money. The performance and profitability of the dredging operation is influenced by a number of factors. It’s a complex process.

Data-driven performance improvement

Sensors on your assets and monitoring systems generate vast amounts of data, including water depths, sediment composition and vessel positioning. With increased connectivity, the Internet of Things, big data and artificial intelligence, this data can be enriched and processed faster than ever before. All this data helps you to gain insight into how your assets are actually performing and to determine whether you are operating according to the dredging plan. To ensure optimal efficiency and profitability, monitoring your vessels and equipment with the use of data can help you improve your dredging operations.

Great value of data

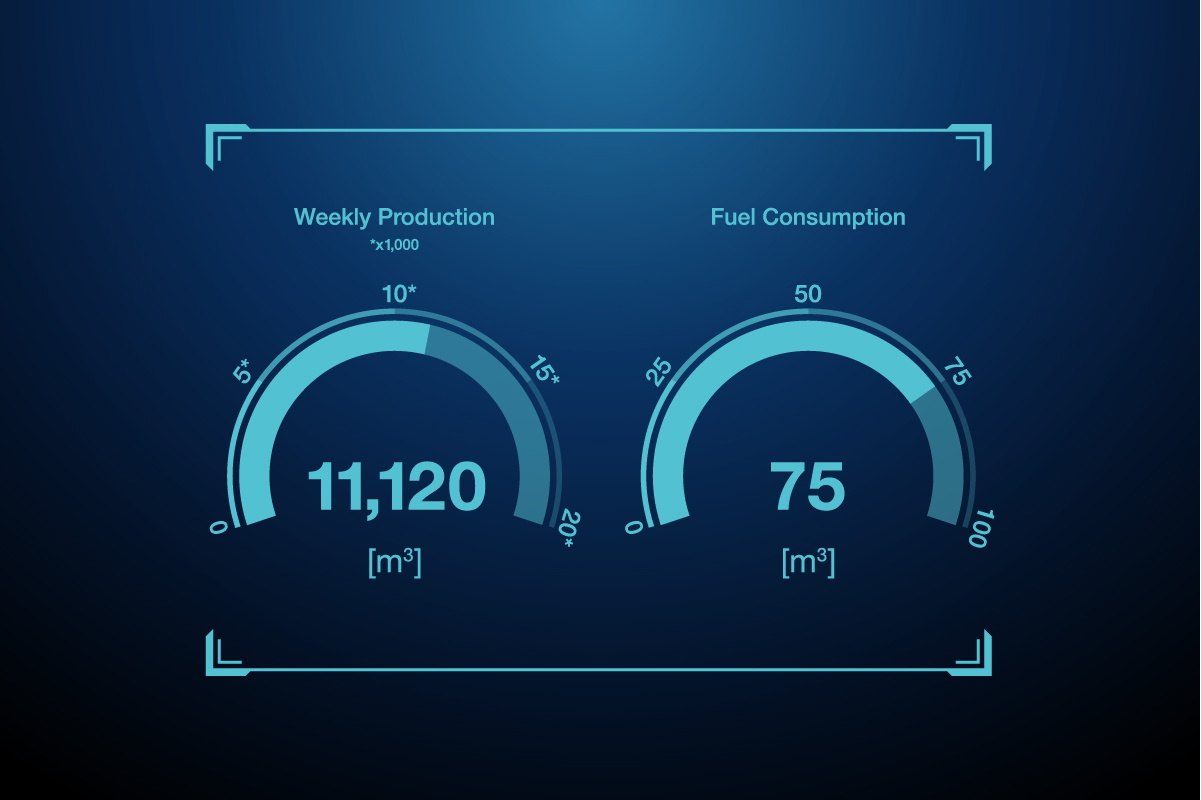

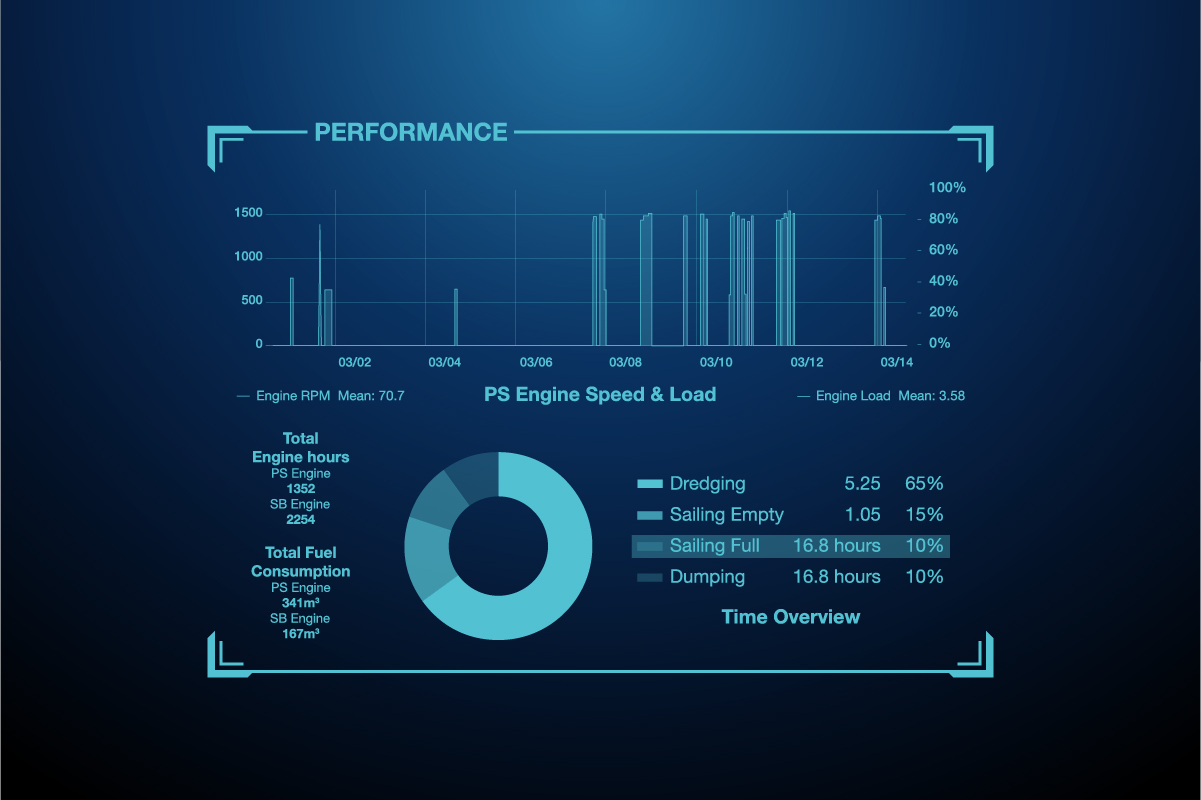

Data contributes to accurate dredging depths, early warning of potential hazards such as underwater obstructions, and optimisation of dredger performance. And it can provide answers to questions such as: Is production on schedule? How can you best schedule essential maintenance to keep your dredging operation running? How can you avoid unplanned downtime and excessive wear and tear? Data can also help you achieve optimum fuel consumption or benchmark the performance of your assets. In short, data can be of great value at various stages of a dredging project by improving operational efficiency, reducing (maintenance) costs and enhancing project timelines.

Right equipment for the job

When you are bidding for a project, you want to know what is the best vessel and equipment for the job. Use data to benchmark a vessel's performance over time to offer a competitive price. If you bid for a job with a certain m3 production per day, you will want to monitor whether you are meeting that target to determine if you are making a profit on the project. By combining vessel data with manual input from crew on board and other data sources, like weather patterns or survey data, you can gain insight into the dredging cycle and the context of operational or technical downtime.

Environmental compliance

Environmental regulations are increasingly driving maritime operations towards a different operational profile. More and more projects are demanding lower emissions, requiring accounting of the emissions produced, or pushing for low emission operation. As alternative fuels are becoming available it is vital to define which selection results in the best performance. And how do you account for the performance? Using the data generated by CO2, NOX and SOX emission management systems or on-board fuel monitoring systems, you can comply with environmental regulations and make data-driven decisions on fuel selection.

Avoid downtime with a data-driven maintenance strategy

What if you could test run a dredger and the necessary equipment before you start your next project and know exactly when and where problems will occur? Using data generated by sensors on the dredger, it is possible to create a virtual representation of the actual vessel or equipment, known as a Digital Twin. This makes it possible to combine actual behaviour with what should be expected. In this way, it is possible to identify equipment degradation, act proactively before serious problems occur and plan maintenance activities.

Condition monitoring

In a predictive maintenance strategy, monitoring the condition of critical on-board equipment such as propulsion (engines, shafts), pumps and hydraulic systems could be used to identify potential problems. Engine health, the performance of the hydraulic system and the wear and tear of components are all important condition indicators. They help to prevent consequential damage that would shorten normal lifespan or lead to breakdowns and major failures. Condition indicators also make it easier to determine the best time to carry out a maintenance job and ensuring that spare parts and specialist support are available when needed.

Improving knowledge of efficiency

Human behaviour is an important factor in the efficient use of dredging equipment. The right behaviour helps to avoid excessive wear and tear and to achieve optimum production levels and fuel consumption, which also leads to reduced greenhouse gas (GHG) emissions. For example, if a pump is cavitating, this will result in lost production and excessive wear. Both of these situations can be easily monitored using asset data and the insights gained can help the crew to act differently in these situations.

Autonomous operations powered by data

With the shortage of skilled seafarers and the need to improve operational efficiency by reducing human error and costs, more complex tasks are being automated or supported from shore. Technological advances are already resulting in less handling for the vessel’s crew and a different deployment of the crew. The move towards (semi-)autonomous operations to optimise performance and profitability is driven by the power of data.

Optimum efficiency, profitability and sustainability

The added value of data in dredging operations cannot be overstated. Data is there to help you monitor and optimise asset performance and maintenance strategies, comply with environmental regulations, increase crew knowledge of operational efficiency and deploy resources more efficiently. Our conclusion is therefore, that there are many opportunities for dredging operators to become more efficient, profitable and more sustainable through the use of reliable data.

Written by Laura Zwaan

Manager Digital at Royal IHC

Want to know more about the value of data in dredging?

Fill in the form and get in touch with one of our experts.