High recovery jigs

High recovery jigs in short

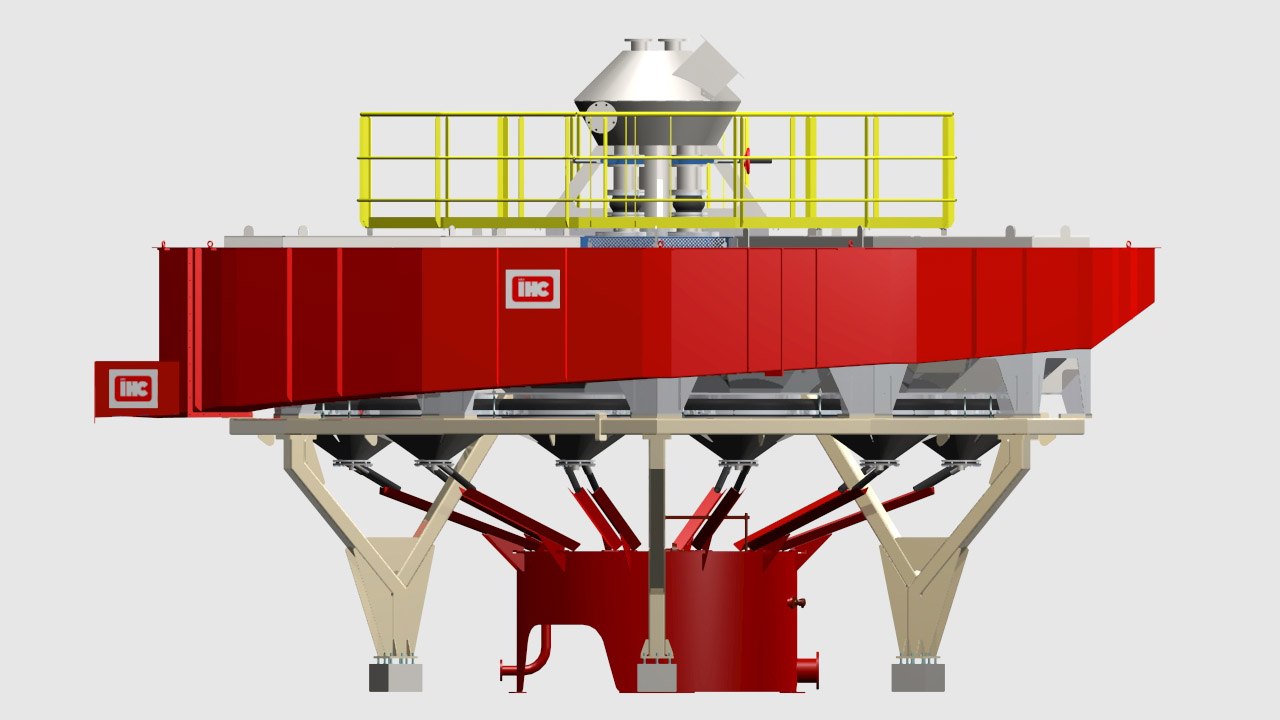

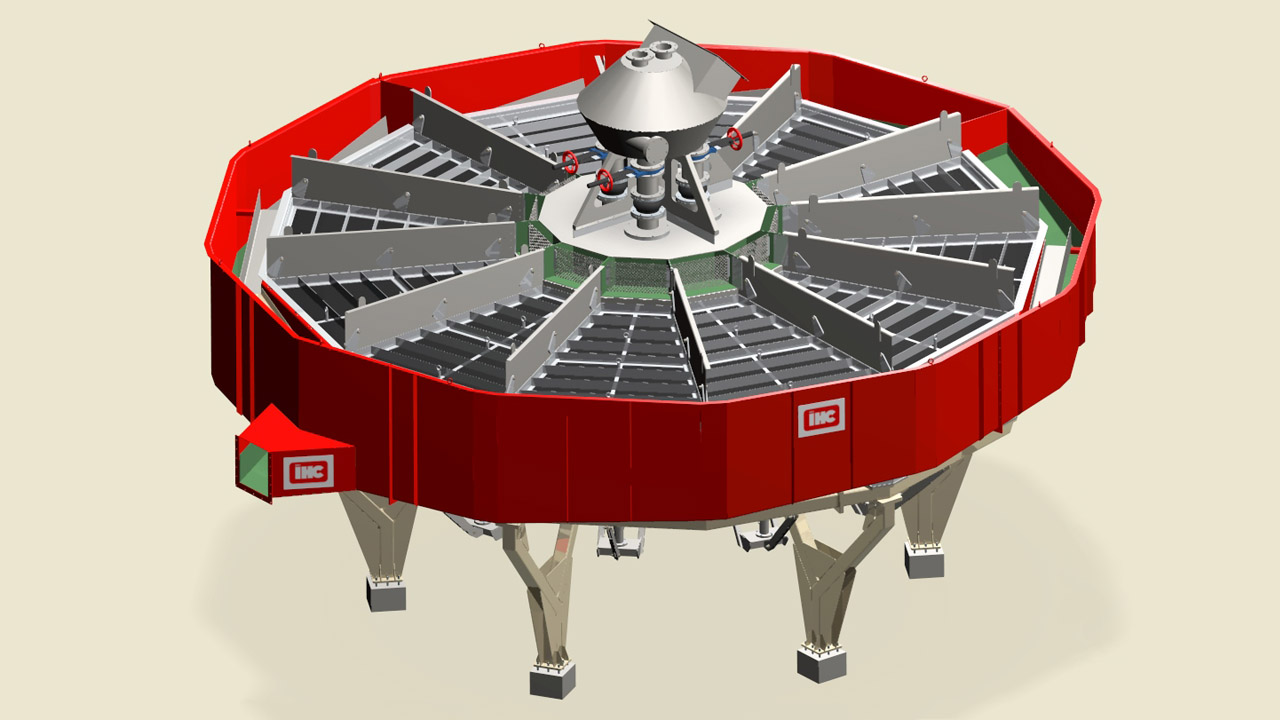

Our high recovery jigs are used in wet gravity concentrations, where minerals with different particle densities are separated. It’s unique saw-tooth stroke pattern and jig design provide a high-unit capacity, high efficiency and optimal recovery.

Why choose our equipment?

- high-unit capacity

- low energy use

- optimal recovery

- robust design

- effective concentration.

From single to integrated

We offer a versatile range of high-recovery jig installations, from single modules to integrated three-stage gravity concentration plants, tailored to individual requirements.

Our jigs are well known for having a large capacity and small footprint. Their modular design, trapezoidal-shaped bed and saw-tooth drive result in an optimal recovery and high upgrade of the valuable heavy mineral, even for the finest particles (down to 50 µm) and at low density differences.

The IHC Mining jig has successfully been used for a range of minerals, including tin, gold, platinum, tungsten, and diamonds, but also in other applications like concentrating valuable metals from bottom ash.

Drive systems

The heart of the IHC Mining Jig is the asymmetrical drive system, which delivers the gravitational movement that separates heavy and light particles in the jig bed. The saw-tooth stroke pattern was developed and introduced to the market by IHC Mining and enables a high-unit capacity and optimal recovery. The system can be both mechanical and mechanical-hydraulic.

For more information, do read our innovation blogs:

- Revisiting high recovery jigs: its development and continued relevance

- Jig testing programme: valuable insights for performance optimisation

More information?

-

Bart

HogewegGeneral Sales Manager

How can we help you?

Looking for advice on our jigs? Fill in the form and our experts will help you.