How does a trailing suction hopper dredger work?

Learn how a trailing suction hopper dredger works.

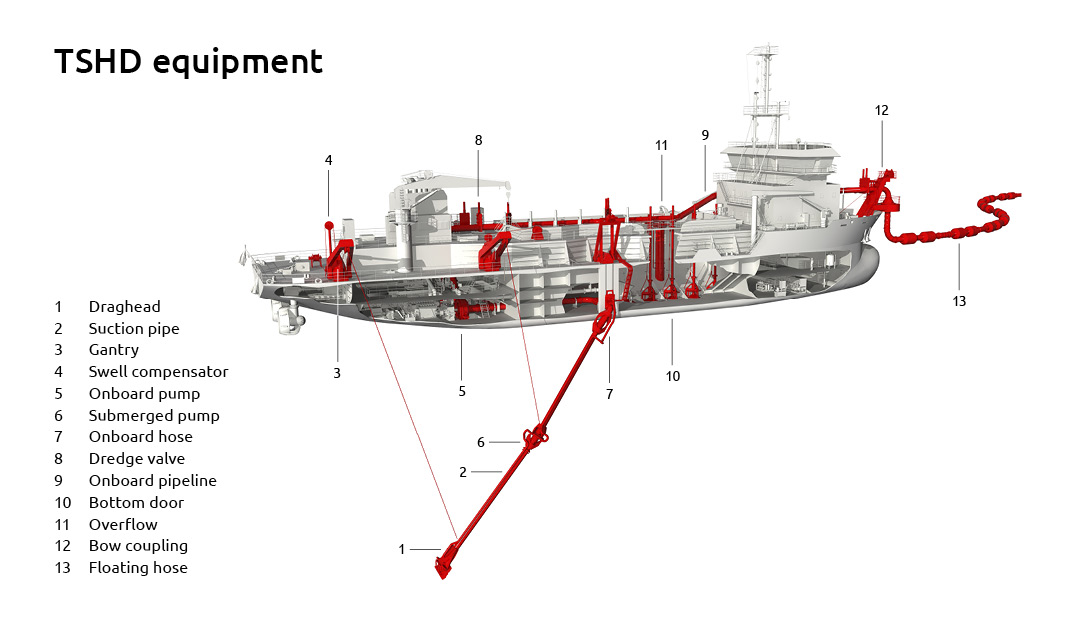

The name trailing suction hopper dredger (TSHD) refers to the fact that this type of vessel dredges while slowly sailing, trailing one or two suction arms off the side of the hull. At the entrance of each suction arm, a drag head is connected. This drag head collects the soil like the mouth of a vacuum cleaner. TSHDs are mainly used to dredge sand, silt and gravel. Compacted sand and coherent soils can also be dredged with special means, such as water jets, blades or rippers in the drag head. Hoppers can easily handle soft and loose soils, such as sand, silt and gravel and have a wide range of dredging projects, including the deepening and maintenance of waterways, land reclamation and port construction, mining and the supply of marine aggregates.

The dredged material is pumped to the hopper, where it is stored for transport. When the hopper is full, the TSHD sets sail to the discharge location. The vessel can empty its hopper in various ways. Depending on the project specifications, the discharge takes place by opening the hopper doors, pumping the material to shore or by ejecting it using a rainbow installation.

The TSHD is a self-propelled, seagoing vessel, and among other advantages, it can be put to work anywhere in the world. Also, it is the only type of vessel that dredges while sailing, making it the dredger of choice for operations in waters where tides and swell occur, and where interference with the movement of shipping cannot be allowed.

Main features of TSHDs:

- hydraulic dredging with one or two dragheads on suction arms and centrifugal pumps

- self-propelled and highly manoeuvrable

- dredges while sailing – making it the dredger of choice for maintenance work, as it does not hinder other marine traffic

- dredged materials transported in the vessel’s well

- suitable for working in open sea, during heavy weather and swell conditions

- discharge via hopper doors, pump ashore facilities or a rainbow installation.

Dredging cycle of a trailing suction hopper dredger

Sailing empty

The first step in the dredging cycle is sailing empty to the area to dredge. In most situations, this means that the TSHD sails from the discharge site to the dredging site.

Dredging

Once the TSHD has arrived at the loading site, the suction arm(s) are lowered off the side of the vessel. The dredge pumps are activated and the dredging begins. When dredging, a mixture of soil and water is pumped into the hopper. At a certain moment, the maximum load of the hopper is reached, and it is filled with sand or gravel and water.

To load more soil, the surplus of water is flushed overboard through the overflow. To reduce the plume created around the vessel, while using the overflow, a special overflow is developed. The overflow is not always used, especially when contaminated materials are dredged (e.g. with maintenance dredging). Most of the particles in the soil will settle in the hopper, but a small part of the sediment flows overboard together with the water. The lighter the soil, the higher the overflow losses are. The losses also tend to increase towards the end of the loading process, especially in lighter sands, so a hopper will never be completely filled with soil.

Loading characteristics of a TSHD depend on the capacity of the dredging installation, the soil to be dredged, the dredging depth, the size of the hopper and the overflow losses that occur during loading. The loading time for a normal TSHD is around one hour. For a gravel dredger, this can be much longer.

Sailing loaded

After loading, the suction arms are raised and the TSHD sails to the discharge area. Sailing times may be short, but can also be very long as is frequently the case during offshore gravel operations or in some land reclamation projects. In case of long distances between the dredging area and the discharge area, the overall production is strongly influenced by the sailing time, as is the dredging cost per m’ or tonnes of dredged material.

Discharge

TSHDs have three methods of discharge. Based on the aim of the dredging project, the project phase and the installed discharge equipment, discharge takes place by:

- Dumping: a normal TSHD discharges its dredged material by dumping through bottom doors – or a comparable bottom discharge system. In case of sand dredging with a conventional TSHD, discharge via the bottom doors takes approximately five to ten minutes.

- Pumping ashore: using the vessel’s own pumps, the sand or gravel is pumped ashore via a pipeline connected to the bow coupling. Pumping ashore time depends on the circumstances, like soil characteristics and discharge distances, but takes around 1.5 hours (for sand). In the case of offshore gravel dredging, the material is generally brought more or less dry to the shore. Special equipment is required and the time for unloading is much longer.

- Rainbowing: this technique is used in shallow locations or ashore, for instance in land reclamation and beach nourishment projects. The sand from the hopper well is discharged to a certain location using the rainbow installation. The name rainbowing refers to the arc shape in which the slurry comes out of the installation. To empty the hopper by rainbowing, even more time is needed compared to pumping ashore.

After the discharging phase, the TSHD will return to the dredging area to continue the dredging cycle.

Want to know more?

Check out our complete overview of our TSHD's and their capabilities