How dredge pumps are becoming increasingly efficient

The performance of any dredger is highly dependent on the efficiency of the dredge pump. That’s why for many years at Royal IHC we’ve been researching how these can work more efficiently. Our findings have led to the development of a new generation of dredge pumps with three major improvements:

- a larger spherical passage to reduce blockage

- improved efficiency compared to the previous generation of pumps

- and greater wear resistance to double the lifespan.

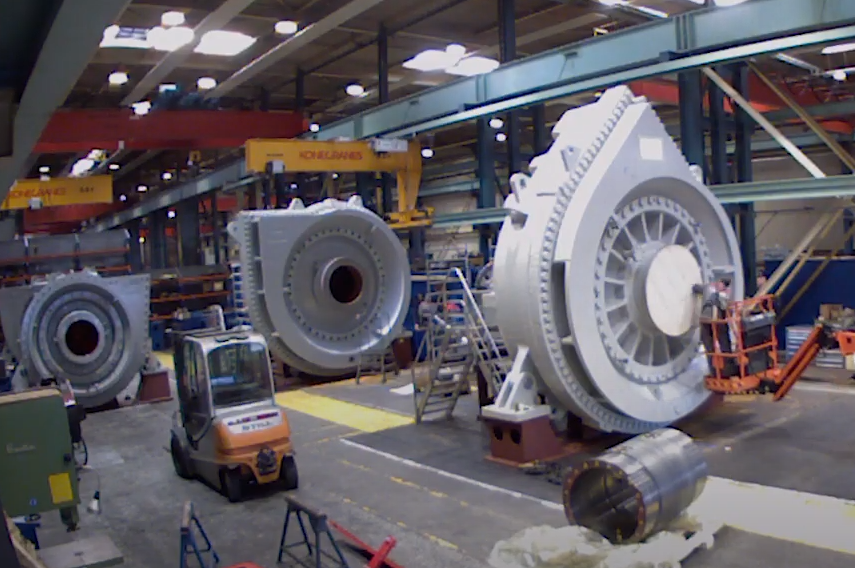

Development of the Cutterspecial® dredge pumps

Cutter suction dredgers (CSD) that encounter rocks and boulders regularly have to deal with blockages in the dredge pump. A blockage leads to downtime of the dredging work and in some cases even damages the pump, which then requires repair.

That’s why Royal IHC introduced the Cutterspecial® dredge pump 20 years ago – with a passage of 50% of the suction opening of the pump, which was significantly larger than the previous generation. Its main advantage is that rocks, which are half the size of the inlet opening, can pass through the dredge pump without causing a blockage.

One step further: even more efficient and wear-resistant

Despite the fact that many dredgers achieved satisfactory results with the Cutterspecial® pump, we believed the dredge pump could be further improved. Measurements in the field and new research techniques led to the development of the Curve® technology, which resulted in a higher efficiency with the dredge pump. In addition, huge steps were taken to improve the dredge pump’s wear resistance. The Cutterspecial® pump with Curve® technology lasts twice as long as the previous generation of dredge pumps.

How much more efficient is Curve® technology?

Let’s focus on how much more efficiency is achieved. By making an adjustment to the impeller blade, the disturbance of the flow in the impeller is reduced to a minimum. This new design of the impeller blade is what we call our Curve® technology.

We calculated that the adjustment of the impeller blades would lead to an efficiency increase of 5.5% for Cutterspecial® pumps, but when we tested the impellers with Curve® technology in the lab, the actual difference in efficiency turned out to be even greater. A Cutterspecial® dredge pump with Curve® technology is 6.5% more efficient than the 'regular' Cutterspecial® dredge pump.

How does Curve® technology work?

Analysis of the flow field in the dredge pump, using computational fluid dynamics (CFD), showed that flow separation was responsible for less efficient operation of the pump. If the inward flow is not properly aligned with the blade, it separates from the surface at the leading edge and creates an area where the flow goes back across the blade.

This separation bubble acts as an obstacle to the main flow in the impeller and causes a chain reaction, and thus disturbance, in the flow over the other blades.

With the Curve® technology we ensure that the impeller blade is optimally aligned with the incoming flow. The flow remains 'stuck' to the surface of the blade, is not disturbed in its intended path and does not disturb the flow around the other blades.

Doubling the lifespan

Even more impressive are the results of improving wear resistance. We see that the Cutterspecial pumps with Curve® technology – supplied to our customers in recent years – last twice as long. In a typical case, a lifespan of approximately 1,400 hours has been measured with a Curve® impeller, compared to a lifespan of 700 hours for a pump with a regular impeller.

On one hand, this is due to a better adjacent flow. And on the other hand, it is because the impeller blades with Curve® technology are much thicker at the front, which faces the heaviest wear. The design has been modified in several places to maximise the life of the dredge pump.

Reducing local wear

The leading edge of each impeller blade has been given an angle. This reduces the impact velocity of the flow onto the blade, meaning less wear and better performance. In addition, the connection between the impeller blade and the front shield has been modified to solve the problem of 'horseshoe vortices' and the resulting wear.

The high velocities within those 'horseshoe vortices' along the front shield eat away at the surface, eventually creating a hole in the front shield. The impeller must therefore be replaced prematurely. Something similar could also be seen along the throat area of the pump housing in the Curve Special dredge pumps. By optimising the volute shape of the pump housing for the flow, the 'horseshoe vortices' have also been significantly reduced here, so that the dredge pump housing also has a longer life.

Backwards compatibility

As only the impeller blades have been modified, the great advantage is that customers who already use a Cutter Special pump only need to replace the impeller to achieve a higher efficiency and extend its lifetime. The same also applies to the dredge pump housing. Existing configurations do not need to be modified.

What about trailing suction hopper dredgers?

The new generation of dredge pumps were initially designed in response to a market demand for CSDs. The results now show that these dredge pumps also perform better in other areas, such as when working with sand and other mixtures. We believe this makes the Cutter Special dredge pump highly suitable for trailing suction hopper dredgers in certain situations.

Development continues

Despite these improvements, our work doesn’t stop and the search for further improvements at Royal IHC continues. Based on the experiences of our customers and our own investment in research, we are continuing to look for technological developments that lead to better performance in terms of the lifespan and efficiency of our dredge pumps. Our continuous journey of discovery symbolises our commitment to helping our customers move forward.

Written by

Hasan Bugdayci

Product manager

Want to learn more about our improved dredge pumps?

Fill in the form and get in touch with one of our dredge pumps experts.