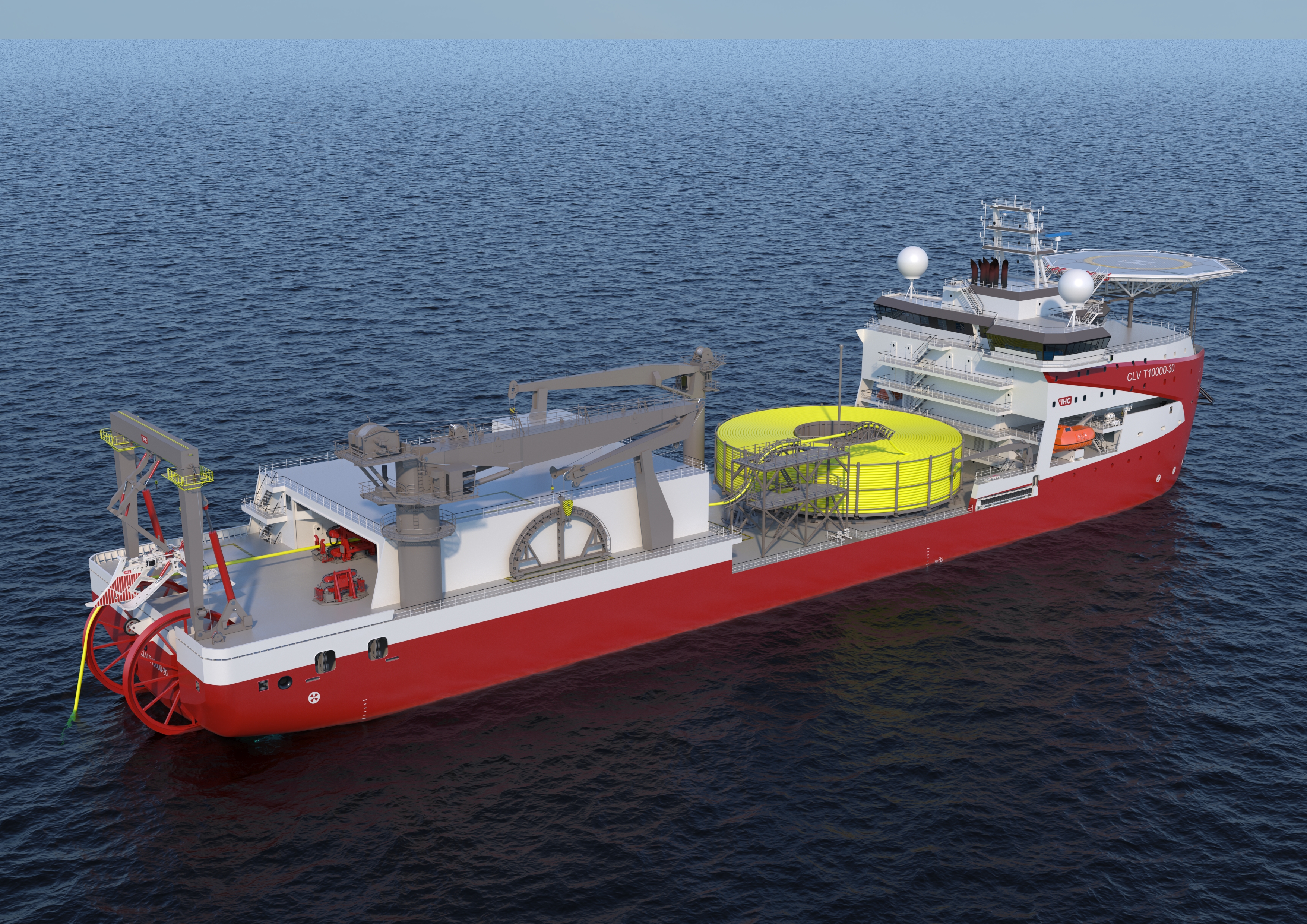

Inter-array cable lay vessel

Cable lay system specific for your mission

Array cables interconnect wind turbines with the offshore substation. With the increasing size of wind turbines, the cable sizes are increasing too and array cables are typically 66kV nowadays. Installing these cables is a delicate task and requires the right asset.

As inter-array cable installation vessels spend the majority of their time offshore installing cables, they are built with a state-of-the-art cable lay system specifically designed for repeating installation sequences of large amounts of array cables, including the latest cable protection systems.

Efficiency benefits

- efficient cable installation

- efficient trenching capabilities

- low fuel consumption (zero emission solutions available)

- excellent seakeeping behavior

-

optimised cable payload capacity.

Built for offshore wind cablelay projects

The CLV T4000-22 is built specifically for offshore wind cablelay projects. The vessel design is based on in-depth knowledge of cable installation operations and experience building highly integrated offshore vessels and equipment. Lean design of material flows and storage has resulted in a vessel sized appropriately for any project. The vessel is optimised for all stages of a cablelay operation, from load-out at the cable manufacturer to burial of the cable into the seabed.

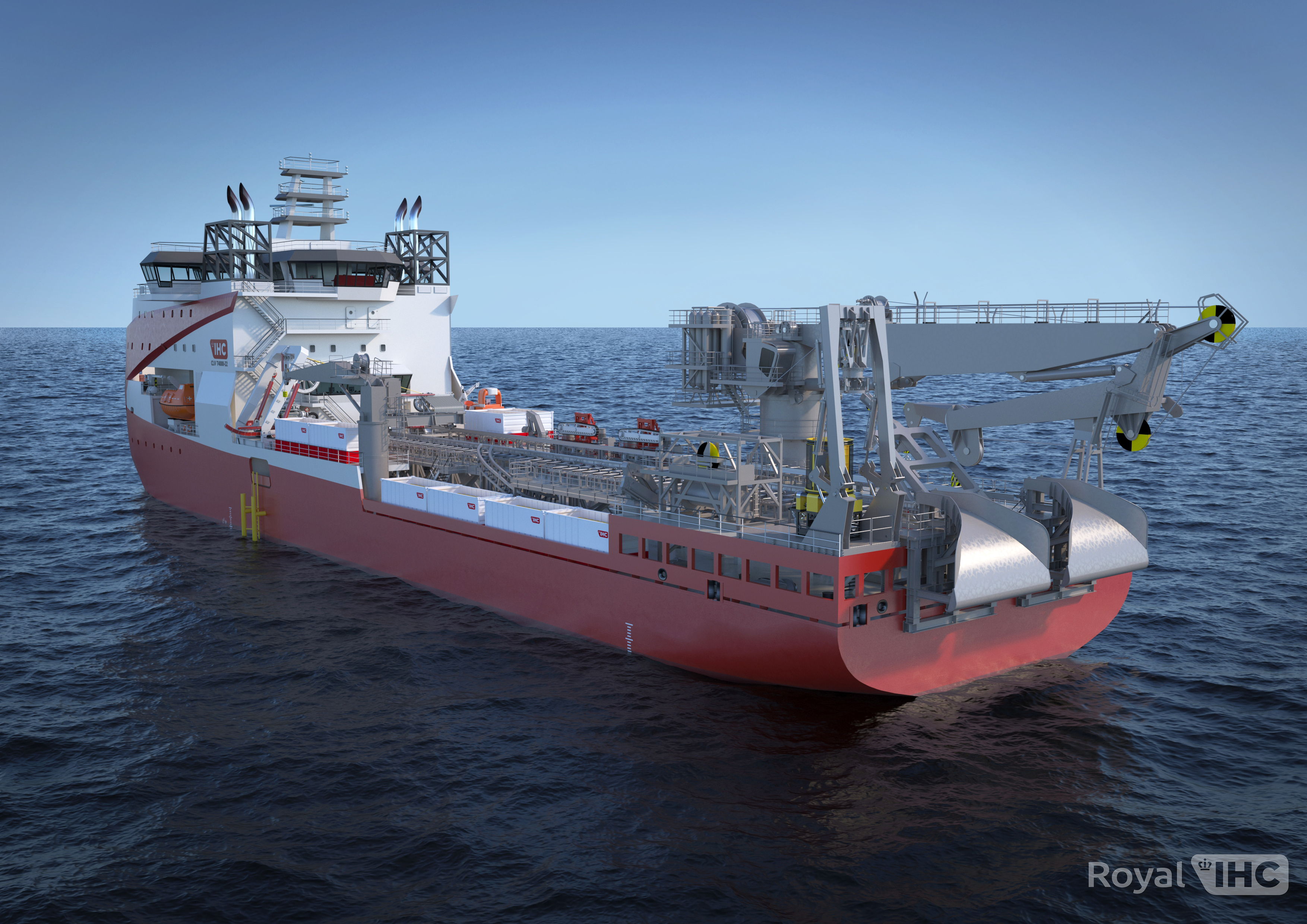

Fast load-outs and plenty deck space

Simultaneous loading

The vessels is outfitted with two carousels which allow for simultaneous loading resulting in fast load-outs and time savings. The cable storage below deck leaves plenty of deck space for cable protection system (CPS) storage and handling.

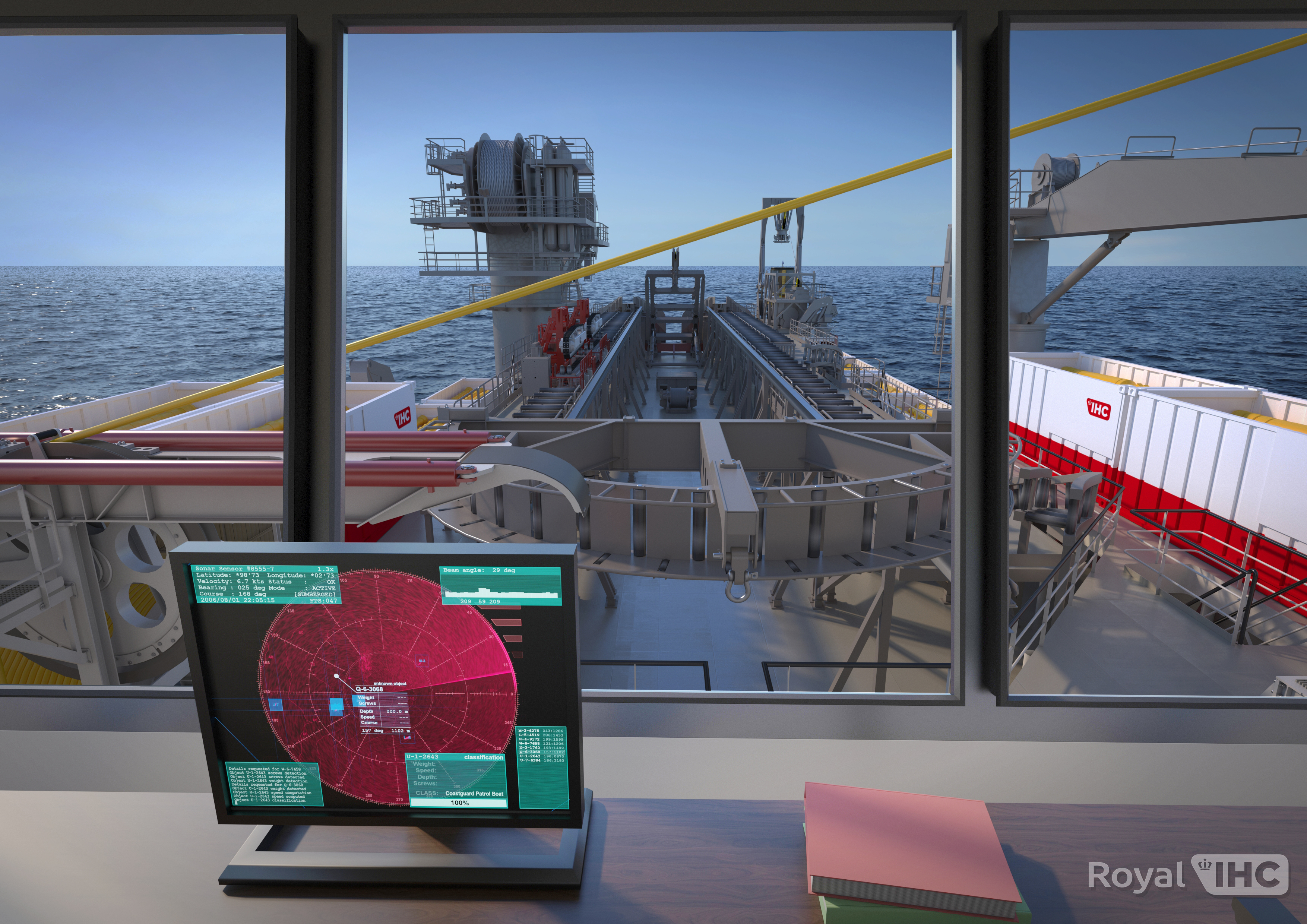

Controlled installation of second cable

A large quadrant and quadrant handling system with active heave compensation allows for smooth and controlled installation of the second cable. The unique quadrant system is placed in-line, eliminating the need to lay cable any further than necessary. The smart design of the quadrant handling system, as well as the chutes allows for flexible heading of the vessel.

Features

- tensioners with breakback functionality

- carousels suitable for different diameters and MBR

- AHC quadrant handling system

- efficient CPS storage and handling

- LARS system for trencher

- large deck space

- integrated cable lay system (modular).

More information?

-

Luuk

KosterSales manager integrated vessels

Can we be of service?

Reach out to our cable lay specialists today!