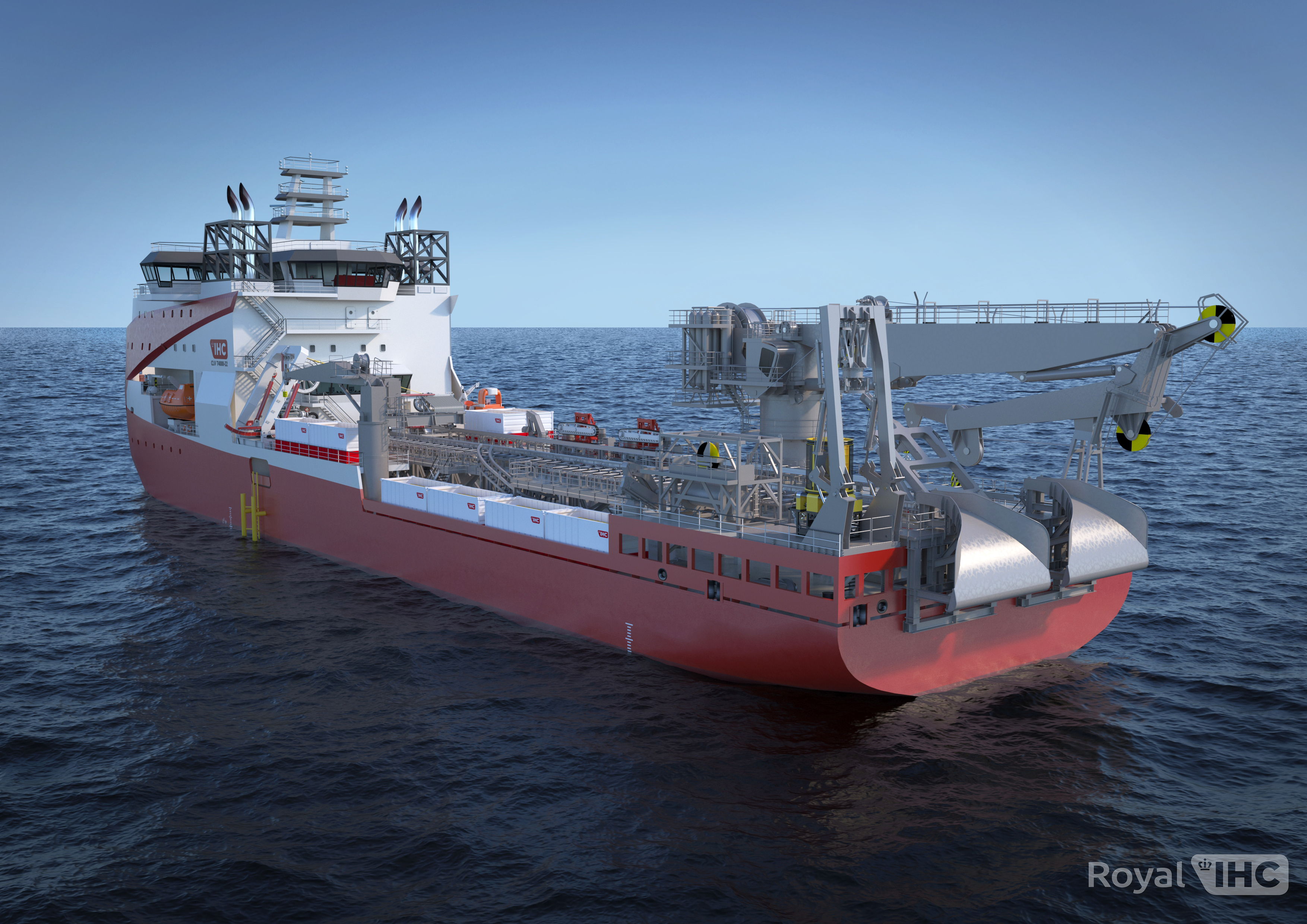

Export cable lay vessel

Installing export cables

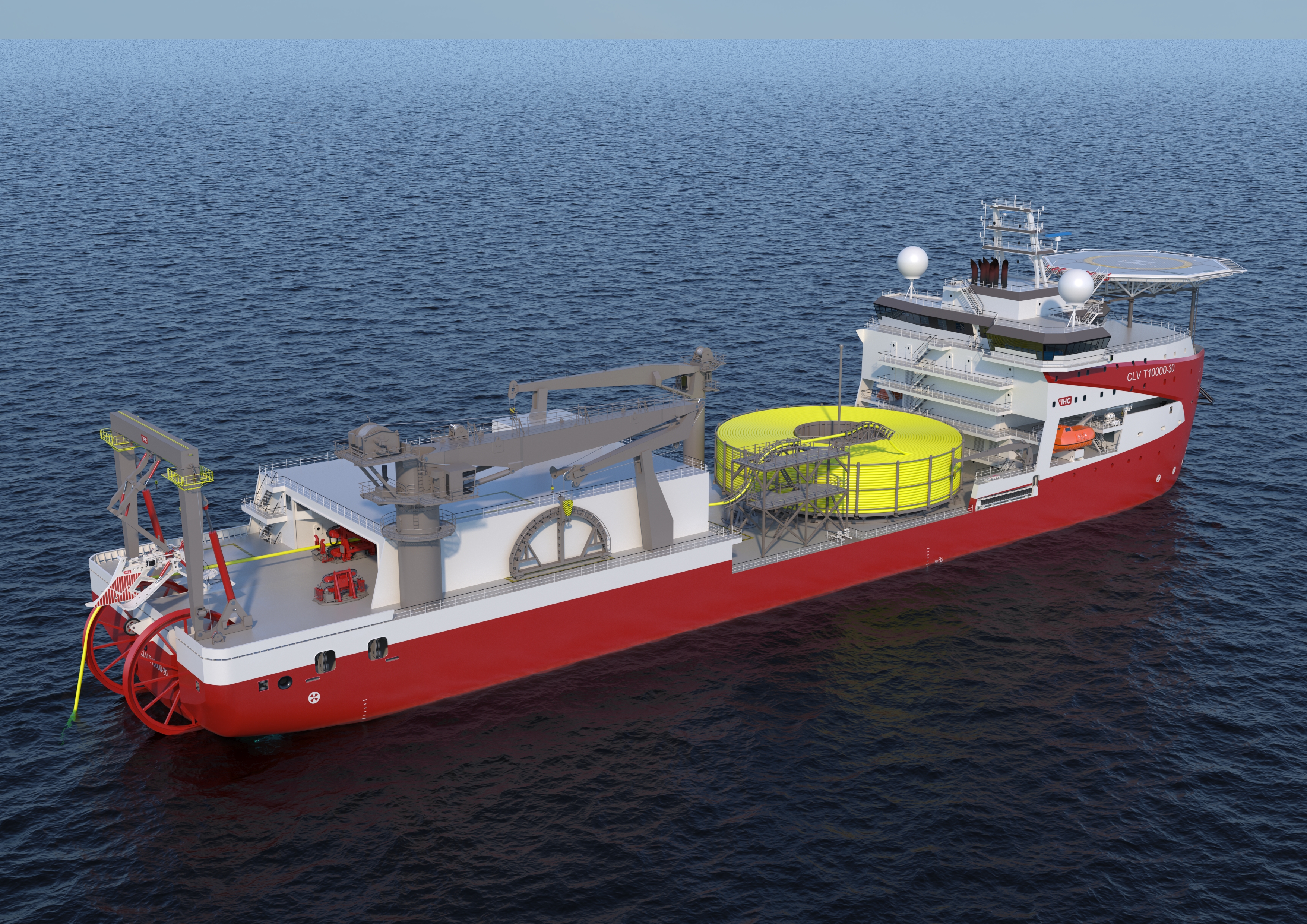

As offshore wind farms are installed further offshore and their size is increasing, the size and length of the export cables are increasing too. Installing and protecting these cables is a delicate task and requires an asset with the right cable payload, mission equipment and endurance.

Mission driven design for cable lay operations

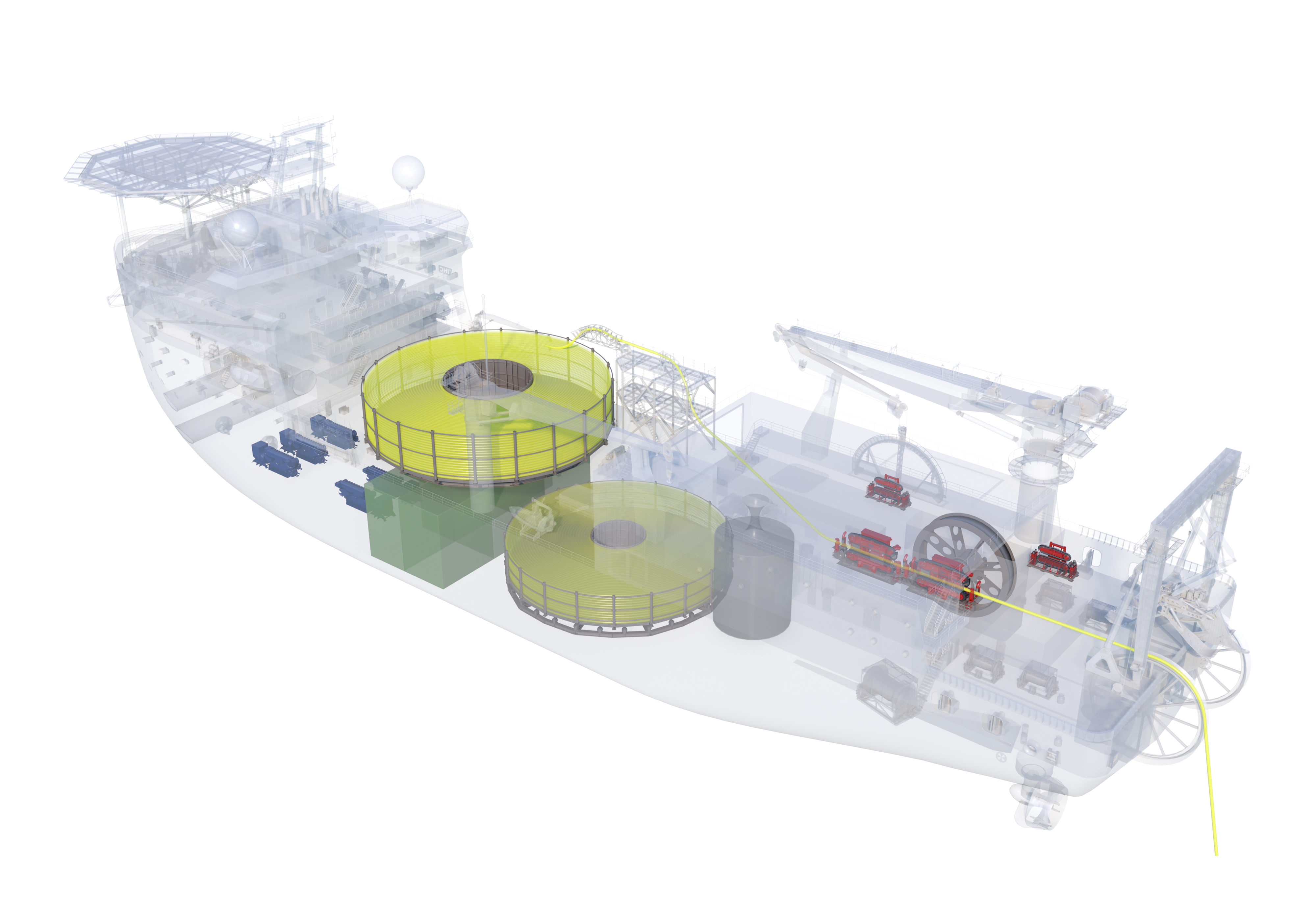

The export cable lay vessel has been designed drawing on our knowledge of cable installation operations in combination with building highly integrated offshore vessels and equipment. A lean design of material flows and storage has resulted in a compact vessel, yet capable of carrying a high payload to enable long stretch operations without the need to re-supply.

The concept designs offers an aggregated 10,500t of cable payload divided between a 7500t carousel on deck, a 5000t carousel in the hold, and a fibre optic tank. The carousel arrangement caters to the different requirements imposed by HVAC and HVDC cables.

Low emission drive

To lower the carbon footprint of the shipping industry we developed this integrated export cable lay vessel, with a low emission drive system aimed at improving the sustainability of the maritime industry.

Read more on our methanol fuelled concept design in our article “The missing link”.

features export cable lay vessel

- high endurance with battery-hybrid methanol propulsion.

- optimised aggregated 10,500t cable payload

- capable of carrying HVAC and HVDC cables

- carriage and deployment of subsea plough

- covered working area on deck

More information?

-

Luuk

KosterSales manager integrated vessels

Looking for the perfect Export Cable solution?

Our experts are happy to help you configure your optimal export cable vessel.