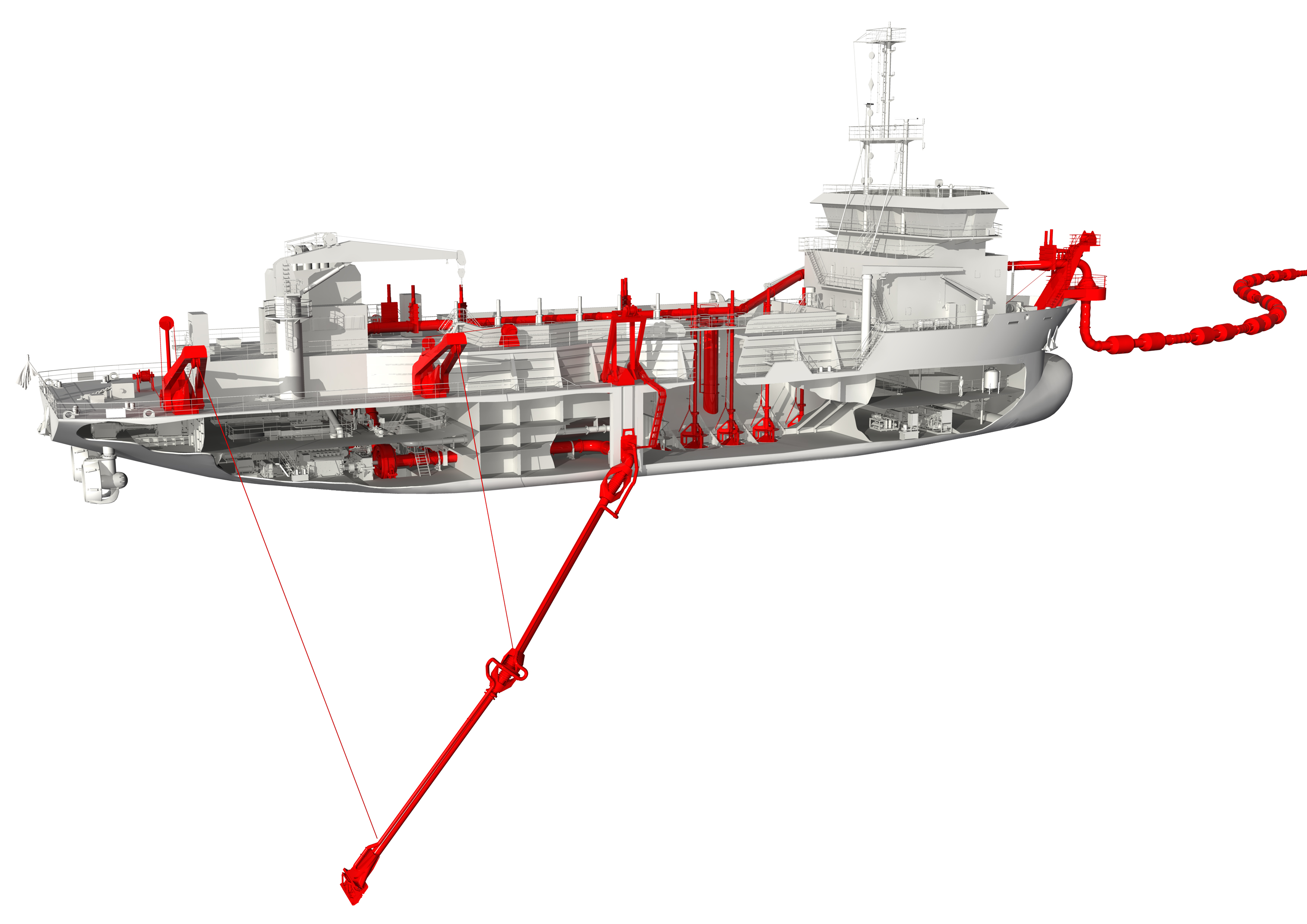

Dredging equipment

Integrated dredging solutions

From vessel to dredger, we offer integrated and tailor-made packages of dredging equipment for optimal dredge performance. Our support consists of designing, manufacturing and building a dredge system for your vessel. Together we create a dredging vessel that suits your dredging projects.

The right equipment for all your dredging challenges

Dredging, whether with a CSD or a TSHD, involves extreme exposure to erosion and causes much of component wear. We have decades of experience addressing the threat of erosion with a range of wear-resistant materials. All dredging equipment in our dredge systems is specially designed to withstand the forces of erosion and corrosion.

Our innovations in dredging equipment

We understand that in challenging dredging environments, having access to the best equipment and the latest technology is vital. Our drive to constantly look for better solutions, as well as new and improved products, ensures that we are able to deliver the best option for any project. Read about our latest innovations:

How can we help you?

Get in touch and one of our experts will help you!